Universal Extruder Frame Hydraulic

Price 12000.0 INR/ Piece

Universal Extruder Frame Hydraulic Specification

- Features

- Frame hydraulic system, heavy duty structure, digital controls

- Response Time

- <1 sec

- Port Size

- DN25

- Resolution

- 0.01 kN

- Display Type

- Digital, LCD

- Max Height

- 1800 mm

- Equipment Type

- Universal Extruder Frame Hydraulic

- Accuracy

- 1%

- Measuring Range

- Up to 500 kN

- Frequency

- 50 Hz

- Temperature

- 10C to 40C

- Power Supply

- 380V/50Hz, 3 Phase

- Test Range

- 10 kN 500 kN

- Application

- Plastic, Rubber, Polymer Extrusion Testing

- Mounting Type

- Floor Mounted

- Number of Specimens

- 1 to 2

- Operating Voltage

- 380V

- Specimen Size

- Standard: 25 mm width

- Hardness

- Robust Structural Frame

- Humidity

- 20%-80% RH

- Gas Pressure

- Max 16 MPa

- Automation Grade

- Semi-Automatic

- Interface Type

- RS232, USB

- Usage

- Industrial Material Testing

- Capacity

- Up to 500 kN

- Machine Weight

- 1400 kg

- Test Speed

- 0.1 500 mm/min

- Test Width

- 300 mm

- Test Stroke

- 250 mm

- Control Mode

- Hydraulic

- Calibration

- Included

- Main Cylinder Stroke

- 250 mm

- Hydraulic Oil Type

- Grade 46

- Power Consumption

- 12 kW

- Oil Tank Capacity

- 60 liters

- Color

- Blue/Grey

- Finish

- Powder coated

- Frame Material

- High-tensile steel

- Piston Diameter

- 100 mm

- Ambient Conditions

- Indoor operation

- Load Cell Type

- Strain gauge

- Safety

- Emergency stop & overload protection

Universal Extruder Frame Hydraulic Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- coimbatore

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- cotton box

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- East India, Gujarat, Kerala, All India, South India, Central India, West India, North India, Karnataka, Lakshadweep, Mizoram, Meghalaya, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, West Bengal, Manipur, Andhra Pradesh, Bihar, Chandigarh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, Jammu and Kashmir, Madhya Pradesh

About Universal Extruder Frame Hydraulic

-

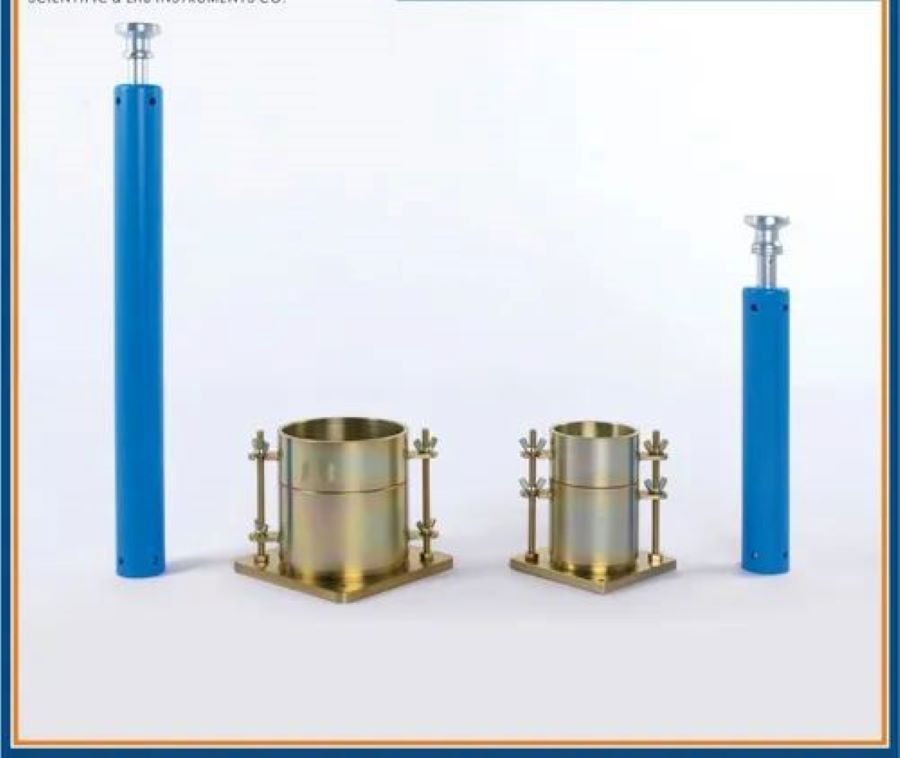

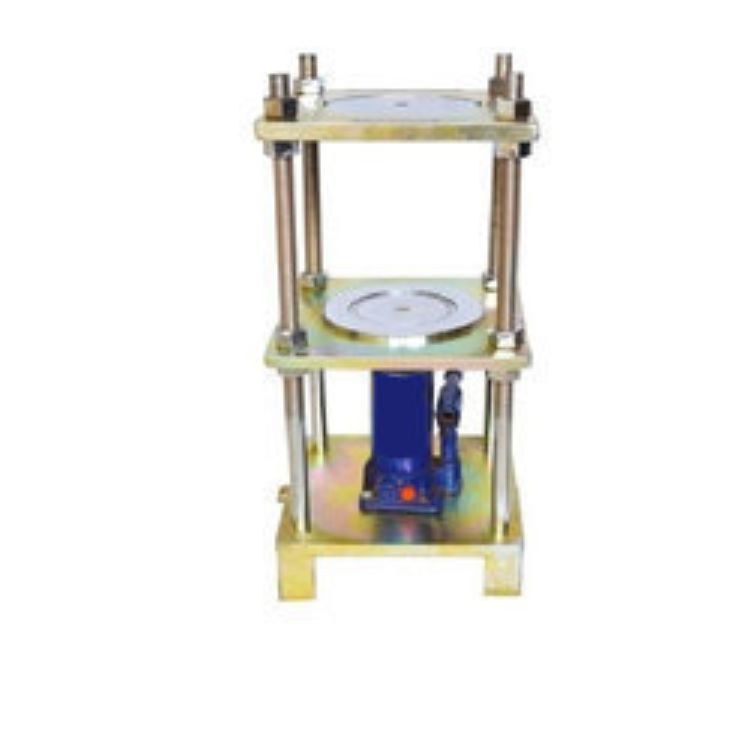

A hand-operated hydraulic jack is mounted on the frame, providing the force for extruding soil samples.

-

The jack usually has a capacity of 50kN.

-

A sturdy frame supports the jack and provides a platform for the soil molds. The frame often has a stable, H-shaped structure for support.

-

The system includes plungers and adapters for different mold or specimen diameters (e.g., 4"/100mm, 6"/150mm, 38mm, 50mm, 75mm).

-

An adjustable thrust plate ensures proper seating of the soil sample within the mold.

- Soil Testing: This hydraulic extruder is designed for soil mechanics applications.

- Sample Preparation: It is used to extrude soil samples from cylindrical molds, preparing them for other tests.

- Strength Testing: The extruded soil core can be used for unconfined compressive strength (UCS) and shear strength tests.

- The equipment is often compliant with standards such as ASTM D1558 and ASTM D2573.

Superior Frame and Hydraulic Power

Constructed from high-tensile steel and finished with a protective powder coat, the extruder frame ensures long-term durability. The hydraulic system, featuring a 100 mm piston and 60-liter oil tank (Grade 46), delivers steady force for reliable testing up to 500 kN. Its heavy-duty structure supports industrial use and frequent sample testing.

Precision Testing and Digital Controls

Designed for accurate material analysis, the equipment utilizes a strain gauge load cell, offering 1% accuracy and 0.01 kN resolution. The digital LCD display with response time below 1 second simplifies data monitoring. With RS232 and USB interfaces, results can be conveniently exported for further evaluation.

Advanced Safety and Calibration Features

Operators benefit from integrated emergency stop and overload protection, ensuring safe operation under varied test loads. The system comes pre-calibrated for immediate use, minimizing setup time. The semi-automatic control mode further streamlines material testing, making it suitable for industrial environments.

FAQ's of Universal Extruder Frame Hydraulic:

Q: How is the Universal Extruder Frame Hydraulic operated for material testing?

A: This equipment uses a hydraulic control system for semi-automatic operation, enabling users to set test parameters and run extrusion tests on plastic, rubber, and polymer specimens with minimal manual intervention.Q: What are the main benefits of using high-tensile steel for the frame?

A: High-tensile steel ensures a robust and stable structure, capable of withstanding heavy industrial loads up to 500 kN, providing enhanced durability and reducing maintenance requirements over time.Q: Where is the Universal Extruder Frame Hydraulic typically installed and operated?

A: The machine is designed for indoor operation in industrial testing environments such as laboratories, production facilities, or research centers requiring precision extrusion testing.Q: What safety systems are included for user protection?

A: The equipment features an emergency stop button and overload protection mechanisms that help prevent accidents and safeguard both the operator and specimen during testing.Q: How is calibration managed, and is it included with the equipment?

A: Calibration is included, ensuring the equipment delivers accurate and reliable readings from the outset. Regular calibration checks are recommended for ongoing precision.Q: What is the process for testing specimens with this machine?

A: Users mount specimens (standard width: 25 mm) in the frame, set the desired test parameters such as speed and load, and initiate the hydraulic system. Results are displayed digitally and exported via RS232 or USB interface.Q: What types of applications is this equipment suitable for?

A: The Universal Extruder Frame Hydraulic is ideal for extrusion testing of plastic, rubber, and polymer materials in research, quality control, and industrial manufacturing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Soil Testing Equipment Category

Standard Compaction Test (BS Version)

Price 9000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Mounting Type : Bench / Table Mount

Power Supply : 220 V AC, 50 Hz

Application : Soil Compaction Test

Control Mode : Manual/Automatic options

Soil Permeability 75 Mm

Price 30000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Mounting Type : Bench Top

Power Supply : 230 V AC, 50 Hz, Single Phase

Application : Determines permeability of soil samples by constant/falling head method

Control Mode : Manual

Vicksberg Pentrometer (Proving Ring Type)

Price 12000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Mounting Type : Bench Top

Power Supply : Not Required (Manual)

Application : Determination of Penetration Resistance of Soil for CBR & Similar Tests

Control Mode : Manual Operation

Heavy Compaction Test (IS)

Price 9000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Mounting Type : Bench/Tabletop

Power Supply : Not required (manual operation)

Application : Soil compaction testing to determine maximum dry density and optimum moisture content

Control Mode : Manual

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry