Standard Compaction Test (BS Version)

Price 9000.0 INR/ Piece

Standard Compaction Test (BS Version) Specification

- Operating Voltage

- 220 V

- Interface Type

- Keypad / Manual Switch

- Humidity

- Ambient

- Display Type

- Analog Digital Indicator

- Frequency

- 50 Hz

- Power Supply

- 220 V AC, 50 Hz

- Automation Grade

- Manual / Semi-Automatic

- Accuracy

- ± 0.1 mm stroke

- Temperature

- Room Temperature

- Hardness

- High-grade steel components

- Number of Specimens

- Single

- Max Height

- 800 mm

- Resolution

- 0.1 mm

- Application

- Soil Compaction Test

- Features

- Robust construction, Adjustable drop height, Conforms to BS specifications

- Mounting Type

- Bench / Table Mount

- Port Size

- Standard Port

- Specimen Size

- 100 mm or 150 mm diameter

- Response Time

- < 1 sec

- Measuring Range

- Moisture-Density Relationship

- Test Range

- Standard Compaction as per BS: 1377

- Usage

- Laboratory Soil Compaction Assessment

- Capacity

- Maximum 4.5 kg with hammer

- Machine Weight

- Approx. 65 kg

- Test Speed

- 47 blows/min

- Test Width

- Standard - as per BS Specification

- Test Stroke

- 300 mm

- Control Mode

- Manual/Automatic options

- Safety Mechanism

- Hammer lock and guard

- Finish

- Powder-coated, corrosion-resistant

- Service Warranty

- 12 months

- Equipment Type

- Standard Compaction Testing Machine (BS Version)

- Mould Material

- Heavy-duty plated steel

- Accessory Pack

- Compaction mould, rammer, tamper included

- User Manual

- Included

- Compliance

- Conforms to BS 1377: Part 4

- Noise Level

- < 65 dB

- Drop Weight

- 2.5 kg and 4.5 kg interchangeable hammers

- Calibration

- Factory calibrated, certificate provided

Standard Compaction Test (BS Version) Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- coimbatore

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- cottonbox

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- Karnataka, All India, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal, Andhra Pradesh, Bihar, South India, Central India, West India, North India, East India, Gujarat, Kerala, Manipur, Lakshadweep, Mizoram, Meghalaya, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Sikkim, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Tamil Nadu, Telangana

About Standard Compaction Test (BS Version)

Specification:

The apparatus consists one each of compaction mould steel, 105mm I.D. x 115.5mm height x 1000 cc. volume, complete with collar and base plate. Compaction Rammer is 2.5 kgs. in weight x 300mm controlled fall. Face of the rammer is 50mm

- Mould: A cylindrical metal mould with a 100 mm internal diameter and 127.3 mm height, providing a volume of 1000 cm. A collar and a detachable base plate are also included.

- Rammer: A 2.6 kg (5.7 lbs) metal rammer with a guide sleeve and vent holes for controlled operation and uniform energy.

- Blow Count: The rammer is designed to deliver a controlled drop of 310 mm.

- Blows per Layer: Each layer is compacted with 25 blows.

-

The soil sample is passed through a 20 mm sieve and mixed with a controlled amount of water.

-

The soil is placed into the mould in three equal layers.

-

The rammer is dropped from the specified height (310 mm) to compact each layer.

-

After compaction, the mould is cleaned and weighed to determine the mass of the compacted soil. A separate sample is dried in an oven to determine the moisture content.

-

The dry density and moisture content are calculated for each trial to develop the dry density versus moisture content curve.

Precision Compaction Testing

Designed to deliver accurate soil compaction results, this machine meets the stringent requirements of BS 1377: Part 4. Its robust construction and adjustable drop height ensure consistent test outcomes with both 2.5 kg and 4.5 kg hammers, catering to varied soil types and laboratory standards.

Comprehensive Safety and Usability

Safety features include an integrated hammer lock and protective guard, ensuring operator security during operation. The machine's intuitive interface, user manual, and accessory pack support ease of use, making it suitable for both manual and semi-automatic testing workflows.

Quality Assurance and Compliance

Factory calibration with certification guarantees measurement reliability, while the powder-coated steel finish offers lasting corrosion resistance. Noise emissions below 65 dB and compliance with BS standards affirm its suitability for professional laboratory environments.

FAQ's of Standard Compaction Test (BS Version):

Q: How is the Standard Compaction Testing Machine operated for soil assessment?

A: The machine can be operated in manual or automatic mode using the provided keypad and switches. Users place the soil specimen in the supplied mould, set the desired drop weight (2.5 kg or 4.5 kg), and initiate compaction at a test speed of 47 blows per minute for precise moisture-density relationship evaluation.Q: What accessories are included with the compaction machine upon purchase?

A: The accessory pack contains a compaction mould (100 mm or 150 mm diameter), rammer, and tamper, all needed for standard soil compaction tests. A user manual and factory calibration certificate are also provided for guidance and quality assurance.Q: When should I calibrate or service the compaction machine?

A: Factory calibration is provided during delivery. For optimal performance, it is recommended to have the machine recalibrated annually. The product comes with a 12-month service warranty, covering necessary maintenance during this period.Q: Where is this equipment commonly used?

A: This compaction testing machine is primarily utilized in laboratory settings, often by dealers, distributors, exporters, manufacturers, and research institutions involved in soil analysis. Its bench or table-mount design supports installation in most laboratory environments.Q: What benefits does the hammer lock and guard safety mechanism offer?

A: The integrated hammer lock and guard protect users by preventing accidental release of the hammer and reducing risk during operation, enabling safer and more controlled compaction processes.Q: Does the machine conform to specific standards or regulations?

A: Yes, the device strictly adheres to BS 1377: Part 4 specifications, guaranteeing accuracy, reliability, and industry compliance for soil compaction testing in professional environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Soil Testing Equipment Category

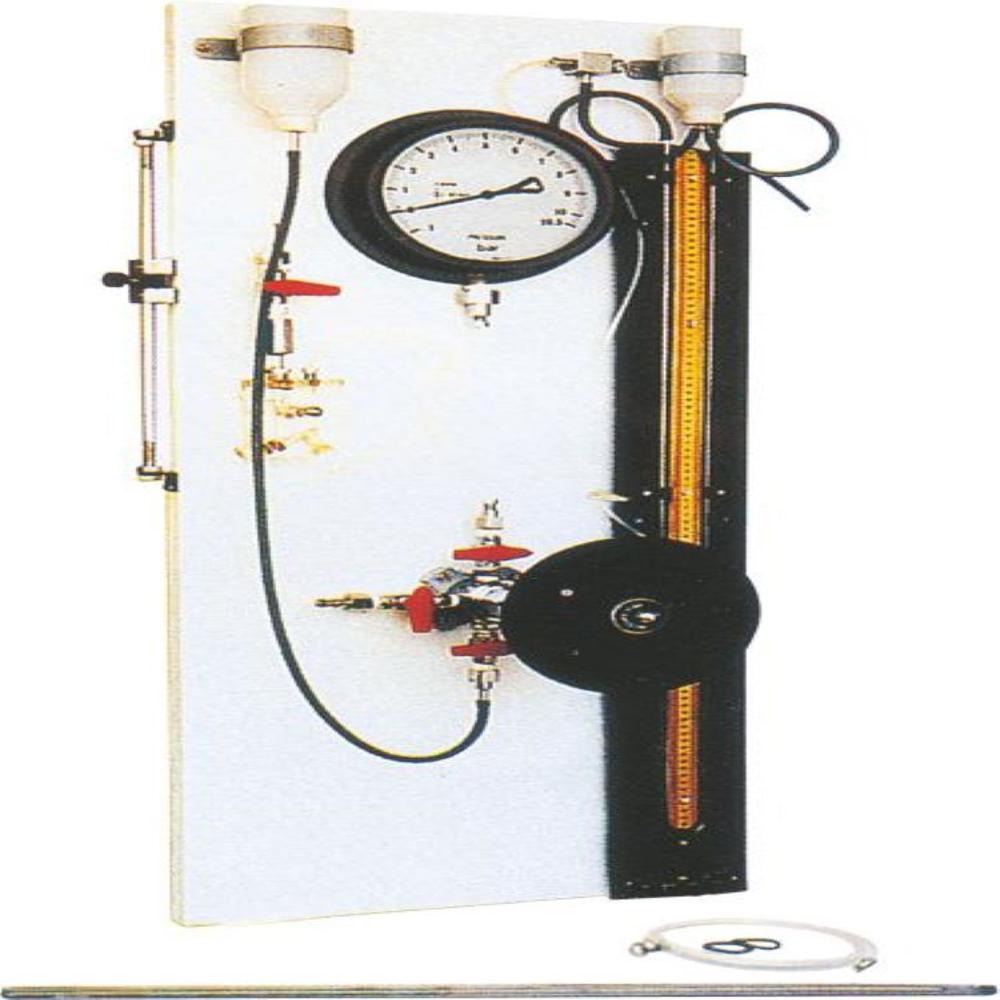

Soil Permeability 75 Mm

Price 30000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Lab/Field Soil Permeability Test

Mounting Type : Bench Top

Display Type : Analog/Manual Reading

Power Supply : 230 V AC, 50 Hz, Single Phase

Pore Pressure Apparatus

Price 25000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Soil testing laboratories

Mounting Type : Benchtop

Display Type : Analog/Dial gauge

Power Supply : 230V AC, 50Hz

Sand Density Cone Apparatus

Price 7000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Geotechnical and civil engineering field tests

Mounting Type : Portable, field use

Display Type : Manual visual measurement

Plasti Limit Set Apparatus

Price 1800 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Display Type : Analog,Digital

Power Supply : AC

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry