Density Of Fresh And Hardened Concrete

Price 21500.0 INR/ Piece

Density Of Fresh And Hardened Concrete Specification

- Number of Specimens

- 1 (per mould)

- Application

- Testing density of fresh and hardened concrete

- Equipment Type

- Concrete Density Measurement

- Response Time

- Immediate, manual

- Humidity

- Relative, as per site condition

- Display Type

- Graduated scale/manual calculation

- Automation Grade

- Manual

- Interface Type

- None (Manual/Baseplate)

- Frequency

- On demand, as per test requirement

- Test Range

- 1800 kg/m to 2600 kg/m

- Temperature

- Ambient/Room Temperature

- Mounting Type

- Tabletop

- Features

- Simple assembly, Portable, Durable, Easy to clean

- Operating Voltage

- Not Applicable; Manual

- Measuring Range

- Up to 3000 kg/m

- Max Height

- Approx. 250 mm with filled mould

- Accuracy

- 1% or better

- Resolution

- 1 kg/m

- Specimen Size

- 150 x 150 x 150 mm cube (standard); Other sizes as per IS standards

- Power Supply

- Not Required (Manual Operation)

- Usage

- Laboratory/Construction Site

- Capacity

- Single specimen per test

- Machine Weight

- Approx. 15 kg

- Test Speed

- Manual Pour & Test

- Test Width

- 150 mm (standard mould)

- Control Mode

- Manual

- Safety Feature

- Ergonomic lift handles for safe specimen removal

- Compliance Standards

- IS: 1199, IS: 516, ASTM C138

- Cleaning Method

- Water and Detergent

- Packing Type

- Cardboard/wooden box

- Waterproof Level

- Yes, for fresh concrete testing

- Material of Construction

- Mild Steel/Aluminum Mould with Smooth Internal Finish

- Colour

- Blue/Gray (Standard)

Density Of Fresh And Hardened Concrete Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- coimbatore

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- cotton box

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- North India, East India, Gujarat, Bihar, Chandigarh, Odisha, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Punjab, Assam, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, All India, South India, Central India, West India, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Daman and Diu, Goa, Jharkhand, Uttar Pradesh, Uttarakhand, West Bengal

About Density Of Fresh And Hardened Concrete

Specification:

The density of both fresh and hardened concrete is of interest to the engineer for numerous reasons including its effect on durability, Strength and resistance to permeability.

Hardened concrete density is determined either by simple dimensional checks, followed by weighing and calculation or by weight in air / water buoyancy methods.

Density of Hardened Concrete:

The density of hardened concrete specimens such as cubes and cylinders can be quickly and accurately determined using a Buoyancy Balance.

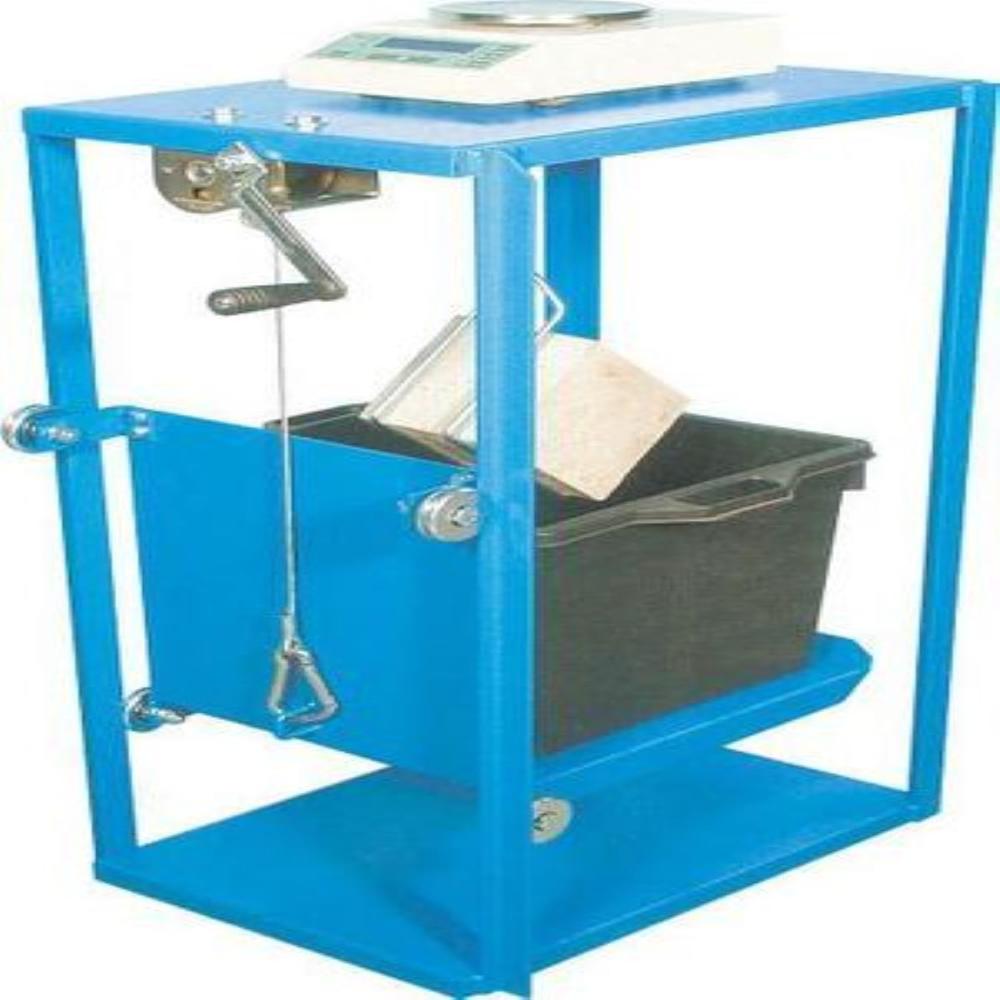

Buoyancy Balance:

The buoyancy balance system developed by us consists of a rigid support frame. Incorporating a water tank mounted on a platform. A mechanical lifting device is used to raise the water tank through the frame height immersing the specimen suspended below the balance fixed on a cradle.

The balance supplied may also be used as a standard weighting device, thus providing a versatile and comprehensive weighing system in the laboratory. The sample is weighed in air and in water to calculate the density of fresh concrete.

Reliable Density Measurement for Concrete

Ensure quality and consistency in your concrete mixes with this manual density measurement apparatus. Built for immediate response and precision, it is ideal for laboratory and on-site use. The waterproof, tabletop construction coupled with ergonomic handles enables safe and efficient specimen handling during both fresh and hardened concrete evaluation.

Compliant, Durable, and User-Friendly Design

This equipment adheres to established standards-IS: 1199, IS: 516, ASTM C138-providing dependable results. Crafted from robust mild steel or aluminum, its smooth internal finish and easy-clean features guarantee longevity and straightforward maintenance. The portable design supports frequent laboratory or field testing with effortless assembly.

FAQ's of Density Of Fresh And Hardened Concrete:

Q: How is the density of fresh and hardened concrete measured using this equipment?

A: Density is determined by placing a concrete specimen in the standardized mould, weighing it, and calculating its density using volume and mass. The device features a graduated scale for direct reading, or results may be manually calculated. The process follows IS: 1199, IS: 516, and ASTM C138 protocols for accuracy.Q: What types of concrete specimens can be tested with this apparatus?

A: The standard mould accommodates 150 x 150 x 150 mm cubes, but other specimen sizes are compatible as per IS standards. The equipment is suitable for both fresh and hardened concrete, with a measuring range of 1800 kg/m3 to 2600 kg/m3, supporting various construction and laboratory needs.Q: Where is this density measurement equipment typically used?

A: It is commonly used in laboratories and construction sites across India for quality control, ensuring that concrete meets specified density requirements. Its portable and manual design makes it adaptable for field or indoor environments without the need for electrical power.Q: When should density testing of concrete be performed?

A: Density testing should be carried out during mix design development, quality control checks, and after concrete curing to confirm performance criteria. Fresh concrete is tested immediately after batching, while hardened specimens are checked post-curing as per project or compliance schedules.Q: What is the cleaning and maintenance procedure for the mould?

A: After each test, the mould and internal surfaces should be cleaned using water and detergent to remove all concrete residues. Regular cleaning maintains measurement accuracy, prolongs equipment life, and ensures smooth specimen removal.Q: What are the benefits of manual operation and ergonomic safety features?

A: Manual operation allows for immediate, on-demand testing without reliance on power supply. Ergonomic lift handles enhance user safety during specimen removal, reducing the risk of injury and making the equipment suitable for repeated use in busy environments.Q: How accurate and reliable are the density measurements provided by the device?

A: The equipment delivers a resolution of 1 kg/m3 and an accuracy of 1% or better, ensuring reliable results for compliance with IS and ASTM standards. Its robust construction and standardized procedures minimize errors, fostering consistent quality control in concrete testing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

High Stability 4 Pillar Compression Testing Machine

Price 120000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Up to 100 kN

Usage : Industrial quality control and laboratory

Power Supply : AC 220V 10%, 50 Hz

Mounting Type : Floor standing

Capping Set (Horizontal)

Price 7000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 1000 N

Usage : Cap torque and sealing strength test

Power Supply : 220 V AC, 50 Hz

Mounting Type : BenchTop

Eco Smart Compression Testing Machine

Price 195000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 2000 kN (200 Ton)

Usage : Industrial/Testing Laboratory

Power Supply : 220V AC, 50 Hz

Mounting Type : Floormounted

Concrete Test Hammer (Schmidt Hammer) N Type

Price 15000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Energy 2.207 Nm

Usage : Field and laboratory testing of concrete strength

Power Supply : Not Required (Mechanical)

Mounting Type : Handheld

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry