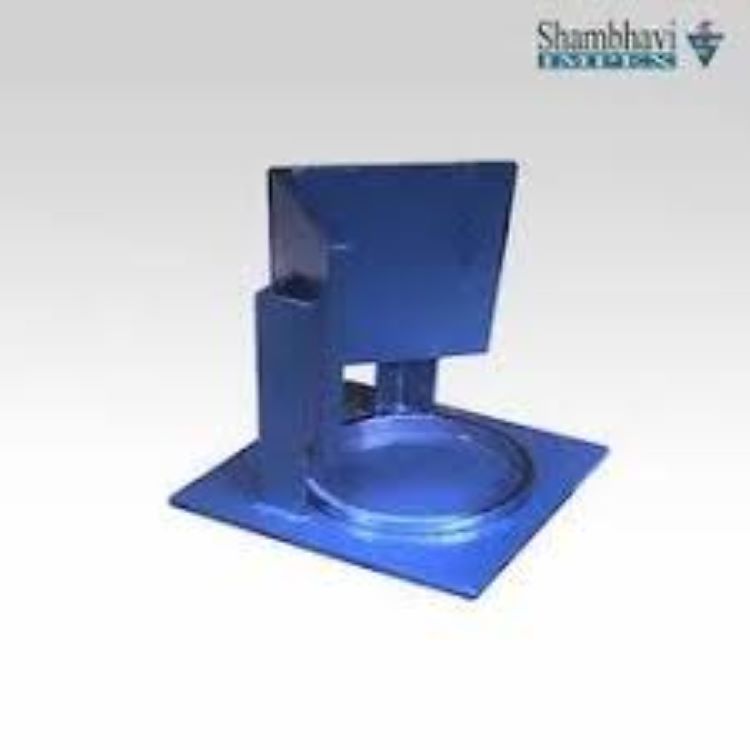

Capping Set (Horizontal)

Price 7000.0 INR/ Piece

Capping Set (Horizontal) Specification

- Max Height

- 350 mm

- Gas Pressure

- 0.30.7 MPa

- Test Range

- 01000 N

- Temperature

- 10C 40C

- Specimen Size

- Standard cap sizes (customizable)

- Power Supply

- 220 V AC, 50 Hz

- Port Size

- Standard compatible

- Interface Type

- RS232/USB

- Resolution

- 0.01 N

- Frequency

- 50 Hz

- Display Type

- Digital LCD

- Response Time

- 1 s

- Humidity

- 85% RH

- Application

- Bottle Cap Sealing/Testing

- Number of Specimens

- 1

- Operating Voltage

- 220 V AC

- Measuring Range

- 01000 N

- Mounting Type

- Bench-Top

- Accuracy

- 0.5% F.S.

- Automation Grade

- Semi-automatic

- Equipment Type

- Horizontal Capping Set

- Features

- Compact design, user-friendly, adjustable parameters

- Usage

- Cap torque and sealing strength test

- Capacity

- 1000 N

- Machine Weight

- Approx. 60 kg

- Test Speed

- 10-500 mm/min (variable)

- Test Width

- 150 mm

- Test Stroke

- Up to 150 mm

- Control Mode

- Digital/Manual

- Safety Features

- Emergency stop, mechanical overload protection

- Compliance

- Meets ASTM/ISO standards

- Fixture Type

- Adjustable clamping

- Operation

- Push-button operation

- Testing Mode

- Cap fitting and removal

- Material of Construction

- High-grade stainless steel & alloy

- Color

- Industrial blue/grey

- Data Output

- Digital report through USB

- Maintenance

- Minimal, easy-clean design

Capping Set (Horizontal) Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- COIMBATORE

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- COTTON BOX

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam

About Capping Set (Horizontal)

Specification:

The set comprises of a cylinder capper, a cylinder carrier and a ladle. The cylinder capper consists of a base on which two accurately machined plates are mounted vertically. One plate is firmly fixed and the other one is adjustable horizontally. Two plates are provided with holders for holding the cylinder in position. The holder are split and the bottom half of each holder is fixed firmly and the top half of each is removable and bolted down to the lower half. On the upper parts of the vertical plates 'V' s are provided for pouring the capping compound. Two spacers are also provided. Complete with cylinder carrier and ladle for molten compound.

ZI 2042A For 150 mm dia. x 300 mm length cylinders

ZI 2042B For 100 mm dia. x 200 mm length cylinders

Precision Engineering for Bottle Cap Testing

Utilizing state-of-the-art technology, the Horizontal Capping Set delivers highly accurate measurements for cap torque and sealing strength. With adjustable digital/manual control modes, it is capable of testing up to 1000 N, ensuring conformance to quality standards. Designed for single-specimen testing, it accommodates standard and custom cap sizes, offering robust performance for diverse industrial needs.

Simple Operation, Enhanced Safety

Safety is prioritized with integrated emergency stop and mechanical overload protection, reducing risk during operation. Its intuitive push-button interface simplifies the testing process, while minimal maintenance requirements and an easy-clean design enhance convenience for regular use.

Comprehensive Data Output and Compliance

The digital LCD display ensures real-time tracking of test results, and data can be exported via USB or RS232 interfaces. The machine strictly adheres to ASTM and ISO standards and is compatible with standard ports, making it a reliable investment for global quality assurance processes.

FAQ's of Capping Set (Horizontal):

Q: How does the Horizontal Capping Set operate for cap testing?

A: The device utilizes both digital and manual control modes with push-button operation, enabling users to test cap fitting and removal by applying variable torque. The process is fully managed through an intuitive interface, and test parameters like speed and force can be easily adjusted.Q: What safety features are included with this equipment?

A: The Horizontal Capping Set is equipped with an emergency stop mechanism and mechanical overload protection to ensure operator safety during testing, minimizing risks associated with mechanical faults or misuse.Q: When should I use this capping set in my production or testing process?

A: This equipment is best utilized during quality control checks or after the capping stage of bottle production to verify torque and sealing strength, ensuring each bottle meets specified industry standards before distribution.Q: Where can this machine be installed in a facility?

A: Designed as a compact, bench-top unit, it can be easily stationed in laboratories, manufacturing lines, or quality assurance departments without occupying excessive workspace.Q: What is the typical process for cleaning and maintaining the capping set?

A: The capping set's minimal, easy-clean design allows users to perform routine maintenance quickly. Simply wipe the external surfaces and removable parts with a suitable cleaner to prevent residue build-up and ensure consistent operation.Q: What benefits does the digital data output provide?

A: All test results are instantly displayed on the digital LCD screen and can be exported via USB or RS232 connections for further analysis. This ensures accurate record-keeping and seamless integration with quality management systems.Q: Can the capping set accommodate different cap sizes and test parameters?

A: Yes, the adjustable clamping fixture and customizable settings make it compatible with standard and special cap sizes. Test parameters such as speed, force, and stroke length can be tailored to fit a variety of application needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

Portable CTM, Hand Operated

Price 38000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Onsite and laboratory concrete strength test

Machine Weight : Approx. 55 kg

Capacity : 100 kN (10,000 kg) / can vary as per model

Test Range : Max. 100 kN (as per model)

Labomix Concrete Pan Mixer

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Concrete Sample Preparation

Machine Weight : 220 kg

Capacity : 40 liters per batch

Test Range : Standard (for concrete mix batching)

J-Ring, Narrow Gap

Price 16500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Testing concrete passing ability through reinforcement

Machine Weight : Approximately 1.5 kg

Capacity : Single unit for one test at a time

Test Range : Suitable for slumpflow range tests

Laboratory Concrete Mixer - Motorised

Price 25000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial Laboratory Use

Machine Weight : Approximately 150 Kg

Capacity : 3, 5, or 7 Litres Drum Capacity

Test Range : For 3, 5 or 7 Litre Capacity Drum

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry