Ring And Ball Apparatus

Ring And Ball Apparatus Specification

- Application

- Determining softening point of bitumen and asphalt

- Accuracy

- 1C

- Number of Specimens

- 2 rings and balls

- Display Type

- Analog

- Interface Type

- Mechanical

- Equipment Type

- Ring and Ball Apparatus

- Automation Grade

- Manual

- Max Height

- Approx. 200 mm

- Features

- Supplied with rings, balls, beaker, assembly;

- Mounting Type

- Bench-top

- Humidity

- Ambient

- Port Size

- Standard laboratory size

- Response Time

- Instantaneous

- Measuring Range

- Ambient to 250C

- Hardness

- Standard brass/rubber balls

- Specimen Size

- Ring: 16 mm dia, Ball: 9.5 mm dia

- Resolution

- 0.1C

- Test Range

- Up to 250C

- Temperature

- Ambient to 250C

- Usage

- Laboratory test for bitumen/asphalt

- Capacity

- Two specimens

- Machine Weight

- Approx. 3.0 kg

- Test Speed

- Manual operation

- Test Width

- Up to 100 mm

- Test Stroke

- Fixed

- Control Mode

- Manual

- Compliance Standards

- IS 1205, ASTM D36

- Stirring Rod

- Glass

- Ring Size

- Internal diameter 16 mm, External diameter 18 mm

- Material of Construction

- Brass, Stainless Steel, and Heat-resistant Glass

- Packed Dimensions

- 250 × 200 × 180 mm

- Ball Diameter

- 9.5 mm

- Operating Environment

- Indoor/Laboratory

- Heating Source

- External (not included)

- Finish

- Polished brass and glass

- Beaker Capacity

- 600 ml

Ring And Ball Apparatus Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- coimbature

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- cotton box

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Rajasthan, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

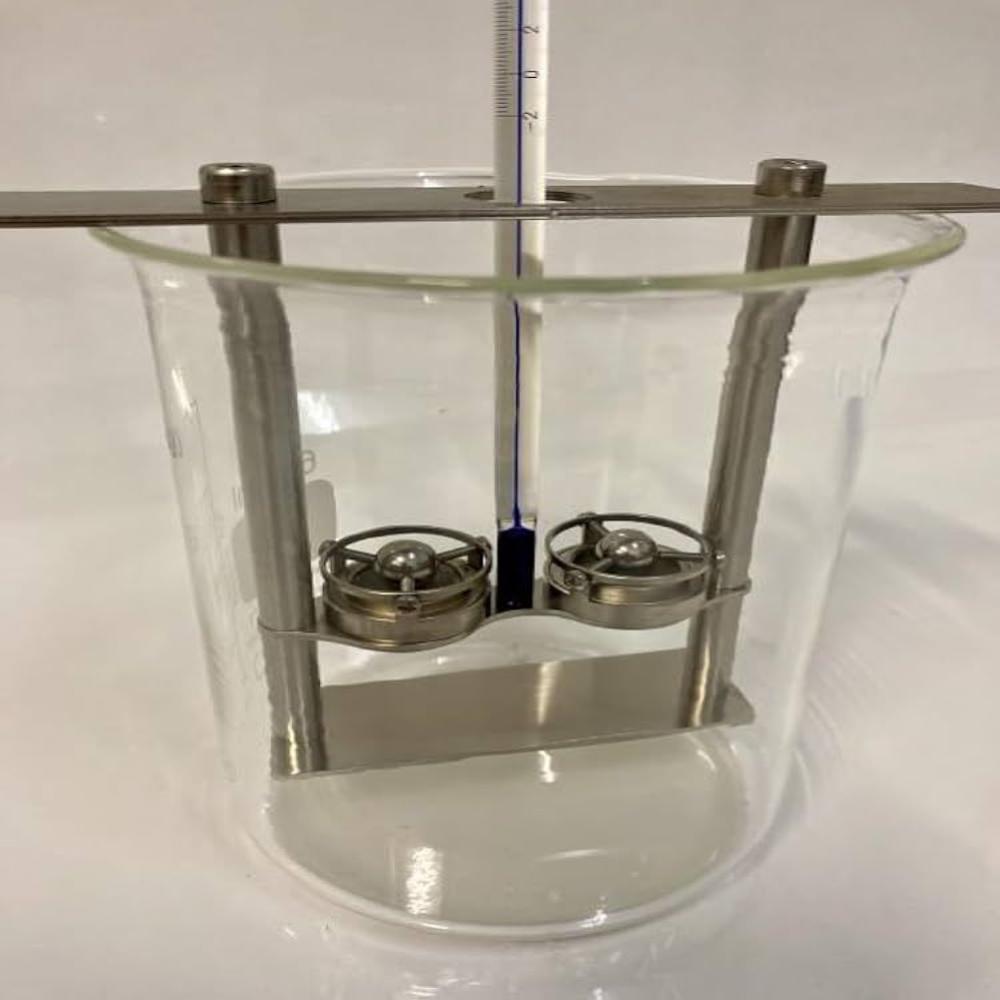

About Ring And Ball Apparatus

- Steel Balls: Two 9.5mm diameter steel balls, typically weighing 2.5 0.05 grams each.

- Brass Rings: Tapered, shouldered brass rings that hold the bitumen sample.

- Ball-Centering Guides: Devices to hold the steel balls in the center of the rings.

- Support Frame: A frame with a sliding plate to hold the rings and allow for the insertion of a thermometer.

- Glass Beaker: A heat-resistant glass vessel, often about 8.5 cm in internal diameter and 12 cm deep, for the heating bath.

- Thermometer: An ASTM or equivalent thermometer to accurately measure the bath temperature, sometimes requiring calibration.

- Heater/Hot Plate: A thermostatic or electronically controlled heater to provide uniform heating to the bath, sometimes with a microprocessor and auto-tune PID controller.

- Stirrer: A hand or motorized stirrer to ensure even temperature distribution throughout the bath.

- Bottom Plate: A plate positioned 25mm below the rings for the balls to drop onto.

-

The apparatus should be able to heat the bath liquid at a uniform rate, typically 5C per minute, as specified by standards like ASTM D36 or AASHTO T53.

-

The support frame should hold the upper surface of the rings 50mm below the surface of the bath liquid.

-

Modern versions may feature digital controllers for precise temperature setting and monitoring, with accuracy specifications.

-

For electrically operated models, specifications include a 230V AC, single-phase, 50Hz power supply.

Precision in Bitumen Testing

Engineered for accuracy in the determination of bitumen and asphalt softening points, this Ring and Ball Apparatus ensures reliable and repeatable results. Its robust construction supports laboratory professionals in conforming to stringent standards and quality controls.

Superior Build and Durability

Constructed using corrosion-resistant brass, stainless steel, and heat-resistant glass, the apparatus withstands rigorous laboratory procedures. Its polished finish and resilient components guarantee a long service life, ensuring value for users in research, manufacturing, and quality testing.

Versatile and Standard-Compliant

Compliant with IS 1205 and ASTM D36, this device is ideal for laboratories, teaching institutions, and quality assurance applications throughout India. The manual control mode allows precise test procedures, while its compact, bench-top design ensures seamless integration into laboratory setups.

FAQ's of Ring And Ball Apparatus:

Q: How do I use the Ring and Ball Apparatus for determining the softening point of bitumen?

A: Place the rings and balls inside the heat-resistant glass beaker, fill it with the sample, and manually operate the heating source (external, not included). Gradually heat the setup while stirring, and observe the temperature at which the balls pass through the softened bitumen. Record this temperature according to IS 1205 and ASTM D36 standards.Q: What materials are used in the construction of this apparatus?

A: The apparatus is manufactured from high-quality brass, stainless steel, and heat-resistant glass. These materials contribute to durability, corrosion resistance, and reliable performance throughout repeated test cycles in a laboratory environment.Q: When should I use the Ring and Ball Apparatus for testing?

A: Use the apparatus whenever you need to determine the softening point of bitumen or asphalt-typically for quality control in construction, asphalt production, or academic research. It is suitable for routine testing in temperature ranges from ambient up to 250C.Q: Where should the Ring and Ball Apparatus be operated?

A: This device is designed specifically for indoor or laboratory environments with ambient humidity and temperature control. Bench-top mounting ensures stability and safety during operation.Q: What benefits does this apparatus offer compared to other testing methods?

A: The Ring and Ball Apparatus provides highly accurate and immediate results (1C, 0.1C resolution) through a straightforward manual process. Its compliance with IS 1205 and ASTM D36 offers assurance of consistent, industry-standard results.Q: How many specimens can be tested simultaneously with this apparatus?

A: The apparatus accommodates two specimens at a time, using two rings and two balls, allowing for parallel and comparative testing to enhance laboratory efficiency.Q: What is included with the apparatus, and is any external equipment required?

A: The package includes polished brass rings, stainless steel balls, a 600 ml heat-resistant glass beaker, a glass stirring rod, and a complete assembly. However, you will need to provide an external heating source for sample testing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Soil Testing Equipment Category

Universal Extruder Frame Hydraulic

Price 12000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial Material Testing

Application : Plastic, Rubber, Polymer Extrusion Testing

Features : Frame hydraulic system, heavy duty structure, digital controls

Measuring Range : Up to 500 kN

Vicksberg Pentrometer (Proving Ring Type)

Price 12000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Soil Penetration & Strength Evaluation

Application : Determination of Penetration Resistance of Soil for CBR & Similar Tests

Features : Portable, Durable, Corrosion Resistant, IS Standard Compliant

Measuring Range : 030 kgf

Ring And Ball Apparatus (Electrical)

Price 10000.0 INR

Minimum Order Quantity : 1 Piece

Usage : Laboratory test for softening point

Application : Determination of softening point of bitumen and resins

Features : Corrosionresistant bath, adjustable heating rate, dual sample test

Measuring Range : Up to 110C

Sand Pouring Cylinder - BS

Price 8000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Civil Engineering, Lab and Field Testing of Soil

Application : Determining insitu density of sand and soil (BS Standard)

Features : Corrosion Resistant, Easy Clean, Durable Brass Construction, Graduated Cylinder

Measuring Range : As per test volume required

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry