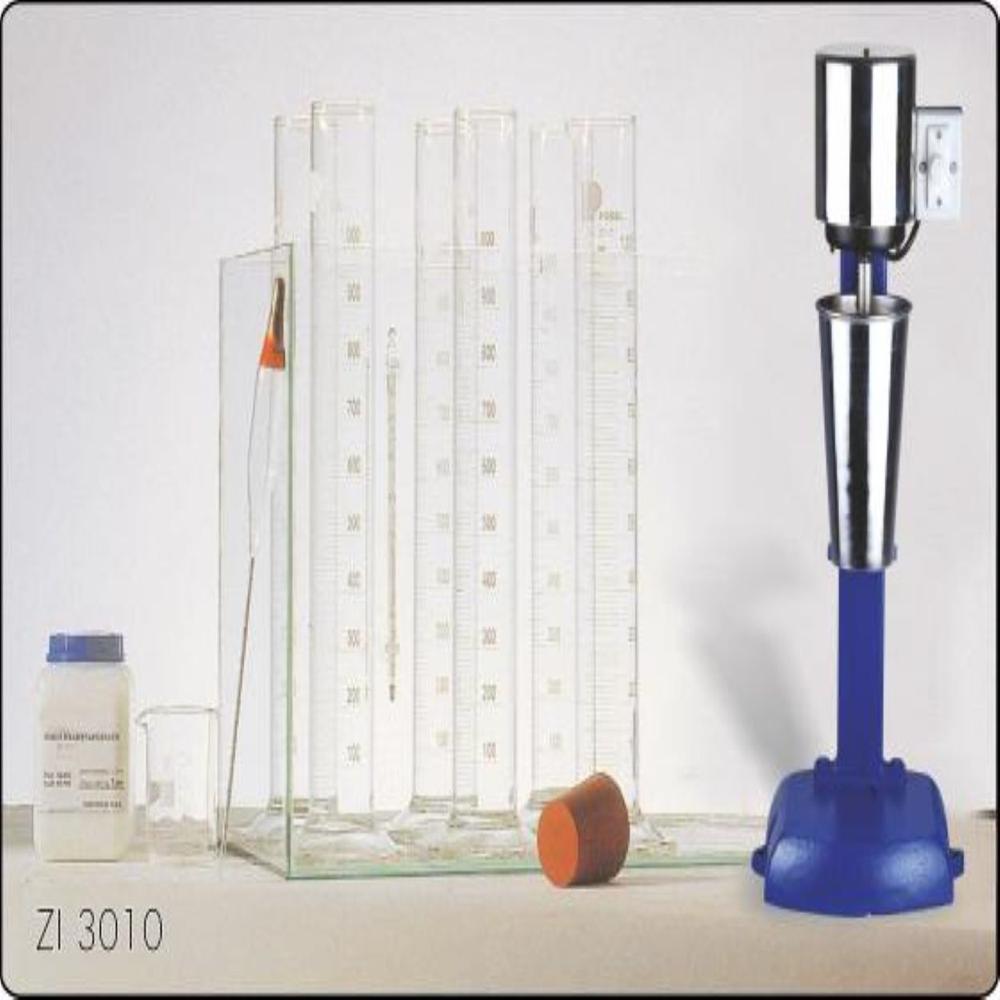

lateral pressure assembly

Price 10000.0 INR/ piece

MOQ : 1 Piece

lateral pressure assembly Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 1 Days

About lateral pressure assembly

Specification:

A lateral pressure assembly spec details the specifications of equipment used to apply cell pressure to specimens in triaxial soil testing, including pressure capacity (e.g., 10 kg/cm), power requirements (e.g., 220-230V, manual or semi-automatic operation), materials (steel, stainless steel), and components like pressure gauges, pumps, and chambers. The exact specifications vary by application and manufacturer, but a typical assembly includes a pressure chamber for triaxial specimens, a pressure gauge to monitor cell pressure, and a mechanism like a foot pump or motor for applying and adjusting the pressure.

Common Specifications:

-

Primarily used in soil mechanics for triaxial testing to apply cell pressure to a specimen.

-

Often around 10 kg/cm, but this can vary depending on the specific model and intended use.

-

- Voltage: Typically 220V or 230V AC.

- Frequency: 50-60 Hz.

- Operation: Can be manual, semi-automatic, or electro-mechanical with controlled loading.

- Voltage: Typically 220V or 230V AC.

-

Common materials include stainless steel or mild steel, with brass components also used for pressure-sensitive parts.

-

- Pressure Chamber: A container that holds the specimen and allows for cell pressure to be applied.

- Pressure Gauge: A dial to monitor the applied cell pressure.

- Pumping Mechanism: A foot pump or electric system to apply and adjust the pressure.

- Accessories: May include flanged top caps, water drains, and air valves.

- Pressure Chamber: A container that holds the specimen and allows for cell pressure to be applied.

-

Ranging from purely manual operation to semi-automatic and electro-mechanical designs.

-

These specifications are variable and depend on the design and manufacturer.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Soil Testing Equipment Category

Particle Size Sedimentation (Hydrometer Method)

Price 15000.0 INR / Piece

Minimum Order Quantity : 1 Piece

We are dealing in Coimbatore, Chennai and Tamilnadu.

GST : 33AVTPM1866A3ZI

SF No. 189/1B1A, 191/3A1A1E, Sidco Private Industrial Estate, LIC Colony, Kurichi Pudhu Nagar, Kuruchi Housing, Coimbatore - 641021, Tamil Nadu, India

Phone :07313727211

|

Branch Address:

No: 15-A/24, Andavar Street, Avvai Nagar,

Choolaimedu , Chennai - 600094

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry