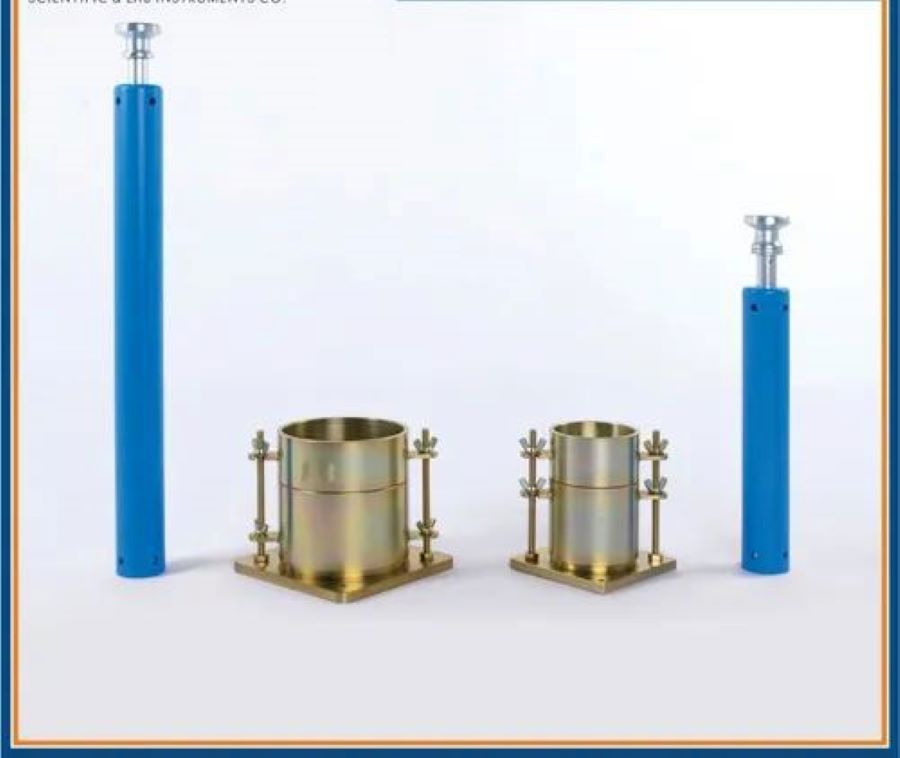

Heavy Compaction Test (ASTM)

Price 4500.0 INR/ Piece

Heavy Compaction Test (ASTM) Specification

- Specimen Size

- 4 (100 mm) or 6 (150 mm) diameter

- Features

- Corrosion resistant, sturdy construction, easy assembly, ASTM compliant

- Measuring Range

- Soil compaction from 1000 kg/m³ to 2500 kg/m³

- Interface Type

- Manual operation

- Max Height

- 600 mm overall

- Display Type

- Analog scale or dial

- Automation Grade

- Manual

- Temperature

- -10°C to 50°C (working range)

- Application

- Laboratory soil compaction tests as per ASTM standard

- Humidity

- Up to 95% RH (operation)

- Power Supply

- 230V AC, 50Hz

- Operating Voltage

- 230V/50Hz

- Accuracy

- ±1% of full scale

- Number of Specimens

- 1 at a time

- Hardness

- Hardened steel hammer

- Equipment Type

- Heavy Compaction Testing Equipment

- Test Range

- Compaction of soils for CBR & Proctor tests

- Mounting Type

- Bench or floor mount

- Response Time

- Immediate mechanical reading

- Frequency

- 50 Hz

- Resolution

- 1 mm (height reading)

- Usage

- Testing soil compaction characteristics

- Capacity

- 4.5 kg (hammer weight)

- Machine Weight

- Approx. 70-90 kg

- Test Speed

- 50-60 blows per minute

- Test Width

- 150 mm (sample mould diameter)

- Test Stroke

- 457 mm (drop height)

- Control Mode

- Manual and mechanical

- Complies With

- ASTM D698, D1557

- Accessories Included

- Moulds, collar, base plate, hammer, tamper

- Drop Hammer Weight

- 4.5 kg

- Compaction Layers

- 5 layers (as per standard method)

- Stand Rod Length

- Over 1 meter

- Finish

- Powder coated/epoxy for extended durability

- Dimensions

- Approx. 700 mm x 400 mm x 300 mm

- Mould Material

- Cast Iron steel

Heavy Compaction Test (ASTM) Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- COIMBATORE

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- COTTON BOX

- Main Export Market(s)

- Africa, Asia

- Main Domestic Market

- Uttarakhand, West Bengal, North India, East India, Meghalaya, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Rajasthan, Sikkim, All India, South India, Central India, West India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Nagaland

About Heavy Compaction Test (ASTM)

Specification:

The apparatus consists one each of compaction mould steel, 152.4mmI.D. x 116.4mm height x 2124 cc. volume, complete with collar and base plate

- Rammer: 10.00-lbf (44.48-N) mass.

- Drop Height: 18.00 in. (457.2 mm).

- Mold: 6-inch (152.4-mm) diameter.

- Layers: 5 layers of soil.

- Blows per Layer: 56 blows.

- Compactive Effort: 56,000 ft-lbf/ft (2700 kN-m/m).

- The soil is prepared with varying moisture content and compacted in the specified mold using the heavy rammer and blows per layer.

- The moist density (or wet unit weight) is calculated for each specimen.

- The dry density is then calculated by accounting for the moisture content.

- These results are plotted to create a compaction curve showing the relationship between moisture content and dry unit weight.

- The maximum point on this curve indicates the maximum dry density (MDW) and its corresponding moisture content, the optimum moisture content (OMC).

-

The test ensures soil is compacted to a desired density for construction projects, such as dams, highways, and runways.

-

It provides data to determine specifications and control the quality of compacted earthfill.

Superior Build and Durability

Manufactured from cast iron steel and finished with powder coated or epoxy surfaces, the compaction apparatus resists corrosion and offers extended service life. The hardened steel hammer and robust design ensure consistent performance under demanding laboratory conditions, making it ideal for repeated use in soil mechanics applications.

ASTM-Compliant Accuracy

Designed to comply with ASTM D698 and D1557, the device achieves high-precision results with an accuracy of 1% of full scale and a height resolution of 1 mm. Immediate analog mechanical readings facilitate efficient and reliable soil compaction evaluations, crucial for roads, foundations, and geotechnical projects.

Versatile Application and Control

Whether mounted on a bench or floor, this equipment supports both manual and mechanical operation modes. It is suitable for laboratories, educational institutions, and field compaction assessments, serving as a vital tool for various stakeholders such as manufacturers, exporters, and research organizations across India.

FAQ's of Heavy Compaction Test (ASTM):

Q: How is the Heavy Compaction Test (ASTM) equipment used in laboratory soil testing?

A: This equipment is used to compact soil samples in a mould with a 4.5 kg drop hammer, following the ASTM D698/D1557 standard. The process involves dividing the soil into five layers, compacting each with repeated hammer blows from a height of 457 mm. The data collected helps determine the optimum moisture content and maximum dry density of soils, which are critical for engineering and construction purposes.Q: What are the main benefits of using this heavy compaction testing equipment?

A: Benefits include accurate soil compaction measurements, compliance with international testing standards (ASTM), sturdy corrosion-resistant construction for long life, easy assembly, and versatile manual or mechanical operation. Its precision and durability make it indispensable for laboratory and geotechnical research settings.Q: When should a heavy compaction test be performed on soil?

A: Heavy compaction tests are essential before construction projects such as roads, embankments, and foundations. They should be performed when you need to assess the compaction characteristics of soils with higher density requirements or when CBR and Proctor tests are specified by project standards.Q: Where is the heavy compaction test equipment typically used?

A: The equipment is suited for soil laboratories, construction sites, and research institutions conducting soil compaction tests according to ASTM standards. Typical users include dealers, distributors, fabricators, manufacturers, exporters, and testing agencies across India.Q: What is the process of conducting a compaction test with this apparatus?

A: The test involves preparing the soil sample, placing it in the cast iron mould in five layers. Each layer is compacted using a standardized number of blows from the 4.5 kg hammer dropped from 457 mm. After compaction, the sample is weighed and measured for density and moisture content, enabling calculation of compaction characteristics.Q: How does the control mode enhance the testing process?

A: The device offers both manual and mechanical operation options. Manual mode lets users control each blow for high precision, while mechanical mode supports standardized and repeatable testing. This flexibility enhances test reliability and ease of use in different laboratory and field settings.Q: What accessories are included with the heavy compaction test set?

A: The set comes complete with moulds, a collar, base plate, hammer, and tamper-everything needed for immediate test setup and operation, streamlining laboratory workflows and reducing time spent sourcing individual components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Soil Testing Equipment Category

Volume Change Gauge

Price 14000.0 INR

Minimum Order Quantity : 1 Piece

Usage : Laboratory soil testing

Power Supply : 220V AC, 50Hz

Port Size : Standard 1/4 inch

Features : Robust frame, digital reading, stable measuring platform

Pore Pressure Apparatus

Price 25000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Soil testing laboratories

Power Supply : 230V AC, 50Hz

Port Size : 1/4 inch BSP

Features : Corrosionresistant parts, robust frame, easy maintenance

In-Situ Vane Shear Test

Price 35000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Geotechnical field testing

Power Supply : Not required (Manual)

Port Size : Standard connection for extension rods

Features : Portable, robust, corrosionresistant finish

Pycno meters

Price 900.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Measurement of specific gravity of liquids

Power Supply : Not Required (Manual)

Port Size : Standard Pycno Meter mouth, approx. 24 mm

Features : Calibrated volume, airtight stopper, chemical resistant glass

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry