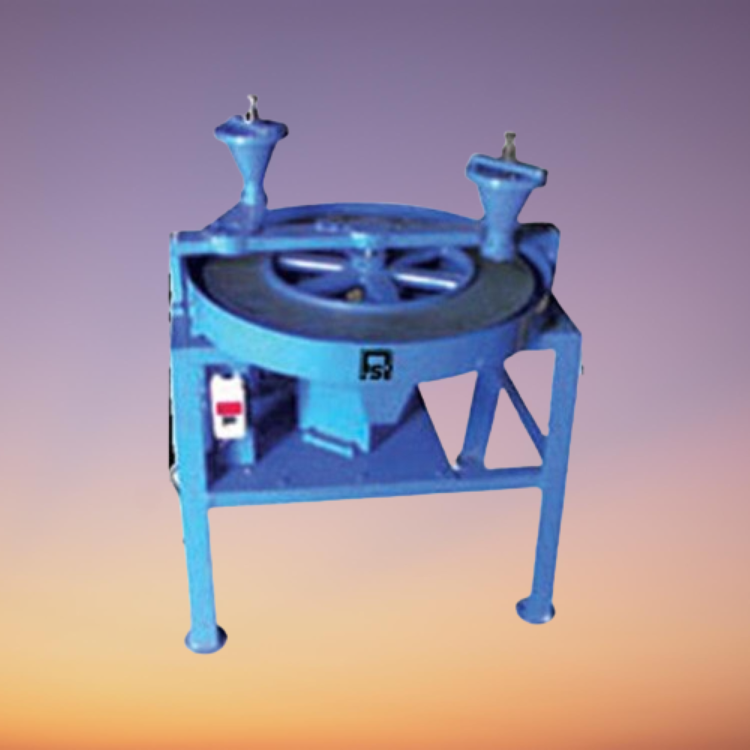

Dorry Abrasion Testing Machine

Price 45000.0 INR/ Piece

Dorry Abrasion Testing Machine Specification

- Test Range

- Aggregate Abrasion Resistance

- Measuring Range

- Up to 500 gm loss

- Specimen Size

- Diameter: 25-50 mm, Height: 25-50 mm

- Mounting Type

- Bench Mounted

- Max Height

- ~30 cm

- Equipment Type

- Dorry Abrasion Testing Machine

- Temperature

- Ambient

- Resolution

- 1 gm

- Features

- Heavy Duty Construction, Corrosion Resistant, Stable Base

- Display Type

- Analog

- Operating Voltage

- 230V AC

- Power Supply

- 230V AC, 50 Hz, Single Phase

- Application

- Aggregate Abrasion Testing

- Response Time

- Instantaneous

- Frequency

- 50 Hz

- Number of Specimens

- 2

- Accuracy

- 1 gm

- Automation Grade

- Manual

- Humidity

- Standard Room Conditions

- Hardness

- Steel components >45 HRC

- Interface Type

- Manual Control

- Usage

- Testing the abrasion resistance of aggregates

- Capacity

- Up to 4 test cycles

- Machine Weight

- Approx. 50 kg

- Test Speed

- 20-30 rpm

- Test Stroke

- 215 mm

- Control Mode

- Manual

- Standard Accessories

- Pair of sample holders, Weights, Abrasive charges

- Abrasive Charge Size

- 50 mm Diameter, 50 mm Height

- Wheel Material

- High-grade cast iron

- Sample Holder Material

- Mild Steel with chrome plating

- Dimension (L x W x H)

- Approx. 600 x 400 x 300 mm

- Rotation Mechanism

- Geared motor system

- Finish

- Powder coated body

Dorry Abrasion Testing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- coimbatore

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- cotton box

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Chhattisgarh, All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Delhi, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal, Meghalaya, Manipur, Andhra Pradesh, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim

About Dorry Abrasion Testing Machine

Specification:

It consists of a disc rotating about a shaft connected to a reduction gear box coupled to a motor. The disc rotates at 28-30 RPM.

Under the rotating disc is a tray with an outlet to facilitate the removal of sand. Two Conical Hoppers are mounted on a bracket fixed to the circular tray. An arrangement is made for start and stop the flow of sand. Two containers with weights are supplied to keep the specimens pressed against the rotating disc.

Suitable for operation on 220 V, 50 cycles, A.C. Supply

Heavy-Duty, Accurate Aggregate Testing

Engineered for high-performance abrasion resistance evaluation, this Dorry Abrasion Testing Machine is crafted with a stable base and corrosion-resistant finish, ensuring reliability in rigorous laboratory environments. Its robust construction and manual interface enable precise control and consistent test results for aggregates, vital for quality assurance in construction projects.

Advanced Features for Consistent Results

Equipped with a geared motor, chrome-plated sample holders, and high-grade cast iron wheels, this machine offers a smooth and controlled testing process. It delivers accurate results (within 1 gm), thanks to instant analog readouts and a manageable resolution, making it suitable for demanding aggregate testing applications across India's supply network.

FAQ's of Dorry Abrasion Testing Machine:

Q: How does the Dorry Abrasion Testing Machine evaluate aggregate abrasion resistance?

A: The Dorry Abrasion Testing Machine determines abrasion resistance by rotating aggregate specimens in contact with abrasive charges on high-grade cast iron wheels. The controlled rotation, powered by a geared motor, enables accurate measurement of material lost (up to 500 gm) after a set number of cycles, helping to assess aggregate durability.Q: What are the standard procedures for operating the machine?

A: Begin by securing two sample specimens into the chrome-plated mild steel holders. Adjust the weights and abrasive charges as required, set the manual controls for rotation speed (20-30 rpm), and run up to four test cycles per session. Weight loss is measured to gauge abrasion resistance, following aggregate testing standards.Q: When should I use the Dorry Abrasion Testing Machine?

A: Use this machine whenever determining the durability and quality of aggregates for construction projects is necessary. It is commonly applied in quality control laboratories, aggregate processing plants, and research institutions to ensure compliance with safety and performance standards.Q: Where can this equipment be installed for optimal performance?

A: The Dorry Abrasion Testing Machine is designed for bench-mounted installation in standard laboratory environments under ambient temperature and humidity. Ensure stable, vibration-free placement near a 230V AC, 50 Hz power supply for accurate and consistent results.Q: What benefits does this machine provide for aggregate testing?

A: This equipment ensures highly reliable aggregate quality assessment, featuring robust and corrosion-resistant construction, easy manual operation, and instant analog displays. Its high measurement accuracy (1 gm) and heavy-duty design reduce maintenance while providing clear, repeatable results.Q: How many specimens can be tested at once, and what are the specimen size requirements?

A: Up to two aggregate specimens can be tested simultaneously. Each sample should have a diameter and height between 25-50 mm, aligning with standard aggregate abrasion test methodologies.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Highway Engineering lab Category

Automatic Grinding Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : 220 V / 50 Hz, Single Phase

Usage : Industrial/Research Lab

Mounting Type : Bench Mounted

Machine Weight : Approx. 50 Kg

Digital Penetrometer

Price 25000.0 INR

Minimum Order Quantity : 1 Piece

Power Supply : 230V AC, 50 Hz

Usage : Laboratory and Field Testing

Mounting Type : Benchtop

Machine Weight : 12 kg

Accelerated Polishing Machine

Price 50000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : 220 V AC, 50 Hz

Usage : Laboratory, Aggregate Testing

Mounting Type : Floor Mounted

Machine Weight : Approx. 120 kg

Automatic Marshall Stability Test Machine

Price 100000.0 INR

Minimum Order Quantity : 1 Piece

Power Supply : 220 V AC, 50 Hz

Usage : Laboratory/Research

Mounting Type : Bench Top

Machine Weight : Approx. 90 kg

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry