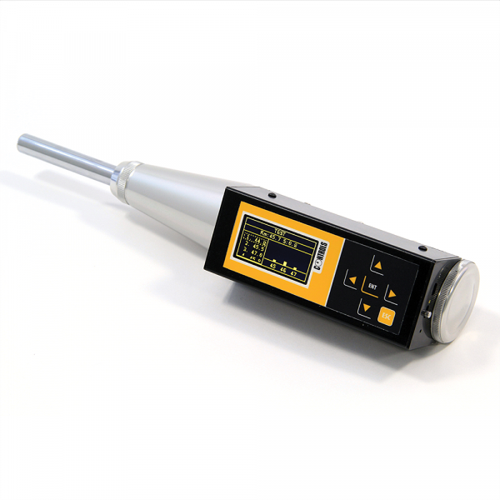

Digital Concrete Test Hammer with Microprocessor

Price 30000.0 INR/ Piece

Digital Concrete Test Hammer with Microprocessor Specification

- Gas Pressure

- Not applicable (mechanical impact)

- Display Type

- Backlit LCD Digital Display

- Humidity

- 85% RH

- Features

- Microprocessor control, data storage, digital output

- Power Supply

- Rechargeable lithium battery

- Frequency

- Manual strike frequency

- Test Range

- 10 to 100 N/mm

- Accuracy

- 1 N/mm

- Temperature

- 0C to 40C

- Interface Type

- USB & Bluetooth

- Operating Voltage

- 3.7V

- Max Height

- Fit for concrete surfaces up to 300 mm

- Mounting Type

- Handheld

- Application

- Non-destructive compressive strength testing of concrete

- Specimen Size

- 150 mm x 150 mm x 150 mm (standard)

- Measuring Range

- 10 to 100 N/mm

- Equipment Type

- Digital Concrete Test Hammer

- Automation Grade

- Automatic calculation

- Number of Specimens

- Up to 10 memory slots per batch

- Resolution

- 0.1 N/mm

- Response Time

- Instantaneous (<1s)

- Port Size

- Standard probe port

- Hardness

- Measures concrete hardness via rebound value

- Usage

- Field and laboratory testing

- Capacity

- Up to 200 measurements per charge

- Machine Weight

- 1.5 kg

- Test Speed

- Standard rebound mechanism

- Test Width

- Applicable to standard concrete specimen width

- Test Stroke

- 18 mm

- Control Mode

- Microprocessor controlled

- User Interface

- Keypad operation

- Body Material

- Aluminum alloy housing

- Shock Value Range

- 10100 units rebound

- Language Support

- Multilingual menu (EN, CN, ES)

- Software Support

- PC data management software included

- Dimensions

- 275 mm 80 mm 55 mm

- Protection Rating

- IP54

- Data Storage Capacity

- Internal memory up to 2000 test results

- Data Export Format

- CSV, PDF

- Calibration Method

- Digital auto-calibration

- Operating Principle

- Mechanical impact with digital readout

- Compliance

- Meets ASTM C805, EN 12504-2 standards

- Battery Life

- Over 8 hours continuous use

- Charging Time

- Approx. 2 hours

Digital Concrete Test Hammer with Microprocessor Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- COIMBATORE

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- COTTON BOX

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- West India, Odisha, Andaman and Nicobar Islands, Lakshadweep, Meghalaya, Bihar, Daman and Diu, Goa, Haryana, Telangana, All India, Central India, East India, Gujarat, Karnataka, Mizoram, Nagaland, Rajasthan, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Tamil Nadu, Tripura, South India, North India, Kerala, Manipur, Andhra Pradesh, Chandigarh, Jharkhand, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Arunachal Pradesh, Chhattisgarh, Himachal Pradesh, Sikkim

About Digital Concrete Test Hammer with Microprocessor

Specification:

This digital concrete test hammer, microprocessor operated, performs basic concrete testing with continuous automatic recording of all parameters in accordance with EN 12504-2 Specifications, register and process data and then transfer them to a PC The unit is equipped with an electronic transducer that measures the rebound values and supplies automatically the results on a graphic display.

During test performing:

- Shows index value

- Shows average index value

- Allows to select measuring system in MpA or Psi

- Shows numbers of performed rebounds

- Shows date and time

- Identifies tested element

- Identifies automatically and shows rebound angle

- Shows battery life

Main features:

- Possibility to store, display on graphic LCD 64x124 and download data to PC over 20000 tests

- Automatic statistical processing and readings

- Automatic conversion of rebound index to equivalent compression strength in psi, N/mm2, kg/cm2

- High accuracy and resolution

Dimensions with case: 330x180x120 mm

Weight: 3 kg

Precision and Reliability for Concrete Testing

Engineered for accuracy and rugged dependability, this digital test hammer offers automated calibration and microprocessor control. Its intuitive keypad interface and instantaneous response time make compressive strength assessment quick and straightforward, while the robust aluminum alloy housing ensures durability in demanding environments.

Advanced Data Management Capabilities

With internal memory for up to 2000 test results and up to 10 user-defined memory slots per batch, the device streamlines results storage and export. Its included PC software supports comprehensive analysis, allowing users to export test data in CSV or PDF format for easy sharing and archiving.

Designed for Versatile Applications

Ideal for dealers, manufacturers, and professionals in the concrete industry, this test hammer is suitable for standard specimen sizes and surface heights up to 300 mm. Automatic calculations and precise digital output enhance productivity for field and laboratory testing in various project settings.

FAQ's of Digital Concrete Test Hammer with Microprocessor:

Q: How does the Digital Concrete Test Hammer ensure accurate compressive strength readings?

A: The device utilizes a mechanical impact mechanism with microprocessor-controlled, digital auto-calibration, delivering reliable readings with an accuracy of 1 N/mm2, and instantaneous response times of less than one second.Q: What is the process for storing and exporting test data from the hammer?

A: Test results are stored internally, with a capacity for up to 2000 measurements. Data export is facilitated via USB or Bluetooth interface, supporting CSV and PDF formats, and can be managed using the supplied PC software.Q: When should I recharge the battery, and how long does it last during operation?

A: The rechargeable lithium battery provides over 8 hours of continuous use per charge. It is recommended to recharge the device after extensive testing, with a full charging time of approximately 2 hours.Q: Where can this test hammer be used effectively?

A: It is suitable for both field and laboratory environments, fitting concrete surfaces up to 300 mm in height and standard specimen sizes. Its IP54 protection rating permits use in moderately dusty or damp conditions.Q: What are the benefits of using a microprocessor-controlled test hammer over traditional models?

A: The microprocessor control provides enhanced automation and calculation accuracy, digital storage of test results, multilingual menu support, and efficient data management compared to manual analog hammers.Q: How do I operate and navigate the multilingual menu options?

A: The device features an easy-to-use keypad operation with a backlit LCD digital display. Users can select languages such as English, Chinese, or Spanish for menu navigation, improving accessibility for diverse users.Q: Can the hammer handle frequent usage for large testing batches?

A: Yes, its robust design supports up to 200 measurements per battery charge and 2000 storage slots, making it suitable for high-volume testing sessions managed via batch memory slots.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

Plate Type CTM, Hand Operated

Price 40000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Not Required (Manual Operation)

Usage : Laboratory Testing, R&D

Application : Coefficient of Friction, Peel Strength, Adhesion Testing

Mounting Type : Table Top

Density Of Fresh And Hardened Concrete

Price 21500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Not Required (Manual Operation)

Usage : Laboratory/Construction Site

Application : Testing density of fresh and hardened concrete

Mounting Type : Tabletop

Concrete Test Hammer (Schmidt Hammer) N Type

Price 15000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Not Required (Mechanical)

Usage : Field and laboratory testing of concrete strength

Application : Testing compressive strength of concrete structures

Mounting Type : Handheld

Sand Absorption Cone And Tamper

Price 3000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Not Required (Manual Equipment)

Usage : Laboratory Testing of Aggregates

Application : Determining the Specific Fine Quality of Sand (Fine Aggregate)

Mounting Type : Portable/Benchtop

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry