Dead Weight Type Oil & Water Constant Pressure System

Dead Weight Type Oil & Water Constant Pressure System Specification

- Automation Grade

- Semi-Automatic

- Interface Type

- Panel mounted analog/digital interface

- Measuring Range

- 0-100 bar

- Port Size

- 1/4 inch BSP

- Features

- Oil & water usage, robust build, anti-corrosive materials

- Temperature

- 0C to 50C

- Display Type

- Analog / Digital

- Test Range

- 0 to 100 bar

- Max Height

- 650 mm

- Specimen Size

- Up to 50 mm diameter

- Hardness

- N/A (not applicable)

- Accuracy

- 0.1% of FSR

- Operating Voltage

- 230V AC

- Application

- Calibration and testing of Pressure Gauges with oil & water

- Response Time

- Instantaneous

- Number of Specimens

- Single sample per session

- Gas Pressure

- 0-10 bar (for calibration)

- Equipment Type

- Constant Pressure System (Dead Weight Type)

- Frequency

- 50Hz

- Power Supply

- 230V AC, 50Hz

- Humidity

- 20% to 80% RH

- Mounting Type

- Table top

- Resolution

- 0.01 bar

- Usage

- Laboratory / Industrial Gauge Calibration

- Capacity

- Up to 100 bar

- Machine Weight

- Approx. 50 kg

- Test Speed

- Variable, adjustable as per requirement

- Test Width

- 155 mm

- Test Stroke

- 0-100 mm

- Control Mode

- Manual/Automatic

- Weight Set

- High Precision Weights upto 100 bar equivalent

- Maintenance Requirement

- Low, easy to service

- Dead Weight Material

- Non-Magnetic Stainless Steel

- Pressure Medium Compatibility

- Mineral Oil, Distilled Water

- Pressure Generation Method

- Dead Weight Piston Mechanism

- Transportability

- Portable for onsite testing

- Media Type

- Compatible with both oil & water

- Data Logging

- Optional Digital Output (on select models)

- Safety Features

- Overpressure Protection

- Calibration Report

- Included (Traceable to National Standards)

- Piston Cylinder Assembly

- Precision Machined & Lapped

- Environmental Compliance

- RoHS Compliant

- System Dimensions

- 650 mm (H) × 350 mm (W) × 400 mm (D)

- Material of Construction

- Stainless Steel / Mild Steel (Powder Coated)

Dead Weight Type Oil & Water Constant Pressure System Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- COIMBATURE

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- COTTON BOX

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Odisha, Punjab, All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Chandigarh, Daman and Diu, Goa, Jharkhand, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

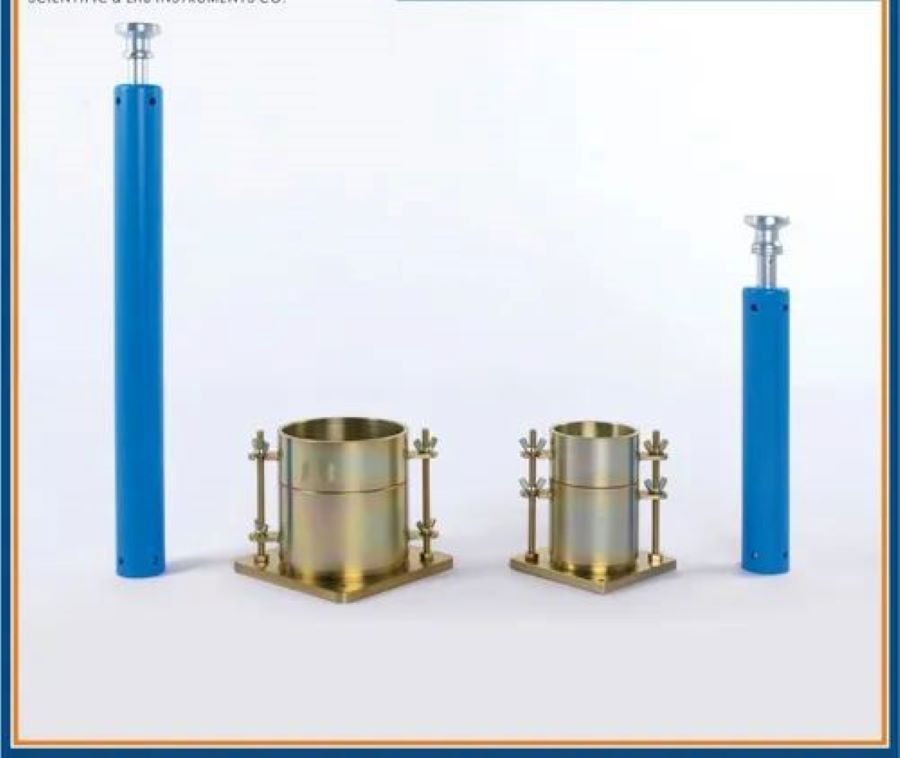

About Dead Weight Type Oil & Water Constant Pressure System

Specification:

This device is used to maintain cell pressure constant for a long duration and the system can be used in place of conventional constant pressure system using mercury pots where certain minimum heights are required. Problems like de-airation of pump, leakage of mercury etc. is eliminated in this system . This unit is smaller in volume and can be used in mobile laboratory also. This can maintain pressure in the cell upto 20kg/cm sq. Pressure is maintained constant in the system by a balancing calibrated weights on a spindle against a column of oil, operating under constant feed back.

Construction:

The system consists of an oil pump continuously driven by an electric motor during the test period. The internal components are housed in a strong compact housing. The piston on which weights are kept rotates with minimum friction. A transparent oil water vessel is provided to transmit pressure to the cell. A hand pump provided facilitates priming and to maintain constant pressure during power failure

Specification :

- Range 0-20 bar(0-20kg/cm2)

- Steps of pressure 0.5bar (0.5kg/cm2)

- Accuracy + 0.5%

- Electric supply 230V, Single Phase, 50Hz, AC supply.

Supplied complete with pressure gauge, flow valves, connecting pressure hose and set of weights to give maximum pressure of 20 bar (20 kg/cm2)

Versatile Media Compatibility

Supporting both mineral oil and distilled water, this system accommodates various calibration needs. The anti-corrosive construction and robust design ensure dependable operation with a range of pressure media, making it suitable for diverse testing environments.

Precision Engineering & Safety Features

Equipped with high-precision weights and a meticulously machined piston-cylinder assembly, this device guarantees measurement accuracy up to 0.1% of full-scale range. Overpressure protection mechanisms safeguard both the equipment and user during high-pressure tests.

Ease of Use and Portability

Weighing approximately 50 kg and featuring a tabletop, compact build, the system is ideal for onsite testing. Its manual and automatic control modes, panel-mounted interface, and low maintenance requirements ensure user-friendly operation in both laboratory and industrial settings.

FAQ's of Dead Weight Type Oil & Water Constant Pressure System:

Q: How does the dead weight piston mechanism generate pressure in this system?

A: The dead weight type system utilizes calibrated, non-magnetic stainless steel weights placed on a precision-machined piston. As the weights apply force, pressure is generated in the oil or water-filled chamber, allowing precise calibration of pressure gauges up to 100 bar.Q: What types of gauges can be calibrated with this constant pressure system?

A: This equipment is designed to calibrate a wide range of laboratory and industrial pressure gauges compatible with oil or water, especially those operating within a 0 to 100 bar measuring range.Q: When should I use oil versus water as the calibration medium?

A: Oil is typically used for general gauge calibration due to its stable properties and low risk of corrosion, while distilled water is preferred when gauge materials are sensitive to oils or where contamination must be minimized.Q: Where can this system be used effectively?

A: Its robust, portable design makes it suitable for both laboratory and industrial settings. It is ideal for onsite gauge calibration due to its manageable size, portability, and straightforward operation.Q: What is the process for maintaining the constant pressure system?

A: Routine maintenance involves cleaning the piston-cylinder assembly, checking overpressure protection devices, and ensuring the weights are free from contaminants. The low-maintenance design allows users to easily service the equipment and ensure continued measurement accuracy.Q: What benefits does the overpressure protection feature provide?

A: The overpressure protection system helps prevent accidental overloading, ensuring user safety, prolonging equipment lifespan, and maintaining the integrity of sensitive pressure gauges during calibration.Q: Is data logging available with this system, and how does it work?

A: Yes, optional digital output for data logging is available on select models. This feature enables users to record calibration data in real time, facilitating analysis, traceability, and reporting for regulatory or quality assurance purposes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Soil Testing Equipment Category

Soil Permeability 75 Mm

Price 30000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Determines permeability of soil samples by constant/falling head method

Power Supply : 230 V AC, 50 Hz, Single Phase

Control Mode : Manual

Mounting Type : Bench Top

Sand Density Cone Apparatus

Price 7000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Used for field density determination of soil by sand replacement method

Control Mode : Manual

Mounting Type : Portable, field use

Heavy Compaction Test (IS)

Price 9000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Soil compaction testing to determine maximum dry density and optimum moisture content

Power Supply : Not required (manual operation)

Control Mode : Manual

Mounting Type : Bench/Tabletop

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry