Laboratory Concrete Mixer - Motorised

Price 25000.0 INR/ Piece

Laboratory Concrete Mixer - Motorised Specification

- Test Range

- For 3, 5 or 7 Litre Capacity Drum

- Automation Grade

- Semi-automatic

- Port Size

- Standard (As per Drum Size)

- Mounting Type

- Floor Mounted

- Features

- Heavy duty, corrosion resistant drum, tilting mechanism, easy loading and unloading

- Frequency

- 50 Hz

- Power Supply

- 220V AC, Single Phase, 50Hz

- Interface Type

- Manual Control Switch

- Specimen Size

- Custom or Standard cube/cylinder specimen sizes (as per IS/ASTM)

- Number of Specimens

- Mixes 1 batch at a time

- Max Height

- Approx. 1000 mm

- Application

- Mixing cement, sand, aggregates for laboratory concrete specimen preparation

- Operating Voltage

- 220 Volt AC

- Equipment Type

- Laboratory Concrete Mixer Motorised

- Response Time

- Immediate upon operation

- Usage

- Industrial Laboratory Use

- Capacity

- 3, 5, or 7 Litres Drum Capacity

- Machine Weight

- Approximately 150 Kg

- Test Speed

- 20-22 RPM

- Control Mode

- Manual / Motorised

- Safety Feature

- Protective cover over motor and transmission

- Colour

- Blue/Gray industrial finish

- Drum Opening Size

- Approximately 250 mm

- Drive Motor Power

- 1 HP electric motor

- Drum Material

- Mild Steel with corrosion-resistant coating

- Construction

- Rugged steel frame

- Mobility

- Fitted with castor wheels for portability

- Drum Tilting

- Gear operated hand wheel

Laboratory Concrete Mixer - Motorised Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- COIMBATORE

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- COTTON BOX

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- Meghalaya, Goa, Jharkhand, Haryana, All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Laboratory Concrete Mixer - Motorised

Specification:

A Concrete and mortar mixer for light professional and DIY use. Designed to give reliable service with low maintenance requirements. The compact storage size makes the Mixer a convenient product for DIY users.

Advantages:

- Light and effective the Mixer mixes a full barrow load

- Compact enough to be transported in the boot of car

- Supplied complete with stand

- Direct drive for increased reliability

- Full thermal overload protection

- 230 V, AC Single Phase

- Drum capacity: 100 Ltrs.

Robust Construction and Safety

This mixer is built with a heavy-duty, corrosion-resistant mild steel drum and a rugged steel frame, ensuring resilience and longevity in laboratory settings. Safety is prioritized with a protective cover over the motor and transmission, reducing risk and enhancing reliability during use.

User-Friendly Operation

Featuring a gear-operated hand wheel for drum tilting and a manual control switch, this mixer offers straightforward and efficient handling. Immediate response upon operation allows seamless integration into laboratory workflows, with easy loading and unloading of materials.

Versatile Mixing Capacity

Accommodating drum capacities of 3, 5, or 7 litres, the mixer is suitable for a range of concrete specimen sizes as per IS/ASTM standards. Its floor-mounted, portable design, fitted with castor wheels, makes it ideal for laboratories requiring flexible and consistent mixing solutions.

FAQ's of Laboratory Concrete Mixer - Motorised:

Q: How do I operate the Laboratory Concrete Mixer - Motorised in a laboratory setting?

A: To operate the mixer, ensure it is connected to a 220V AC power supply. Use the manual control switch to start the motor, then load your materials into the drum. Tilt the drum using the gear-operated hand wheel for easy loading and unloading. Follow standard laboratory safety precautions during use.Q: What is the typical application of this concrete mixer in a laboratory?

A: This mixer is primarily used to prepare concrete specimens for laboratory testing, mixing cement, sand, and aggregates efficiently to produce batches for cube or cylinder specimen sizes as per IS/ASTM standards.Q: When should I use this mixer instead of traditional mixing methods?

A: Choose this mixer when you need consistent, repeatable mixing for concrete specimen preparation, especially when preparing batches for standardized testing in laboratories. Its motorised operation provides uniform results and reduces manual effort.Q: Where can the mixer be installed for optimal use?

A: It is best installed on a stable, flat laboratory floor, thanks to its floor-mounted design and castor wheels for easy relocation. Ensure sufficient space for loading/unloading materials and for safe operation around the protective motor cover.Q: What is the mixing process with this equipment?

A: The process involves loading the required quantities of cement, sand, and aggregate into the drum, activating the motor by the control switch, and allowing the drum to rotate at the specified speed (20-22 RPM). Once mixing is complete, use the drum tilting mechanism to unload the mixed concrete for specimen casting.Q: How does the mixer benefit laboratory operations?

A: This mixer enhances laboratory productivity by delivering immediate mixing response, consistent results, and safe operation. Its versatile capacity accommodates varying batch sizes, and the robust construction allows repeated use in demanding environments.Q: What specimen sizes and batch capacity does the mixer support?

A: The mixer supports batches for 3, 5, or 7 litre drum capacities and is suitable for custom or standard cube/cylinder specimen sizes in accordance with IS and ASTM requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

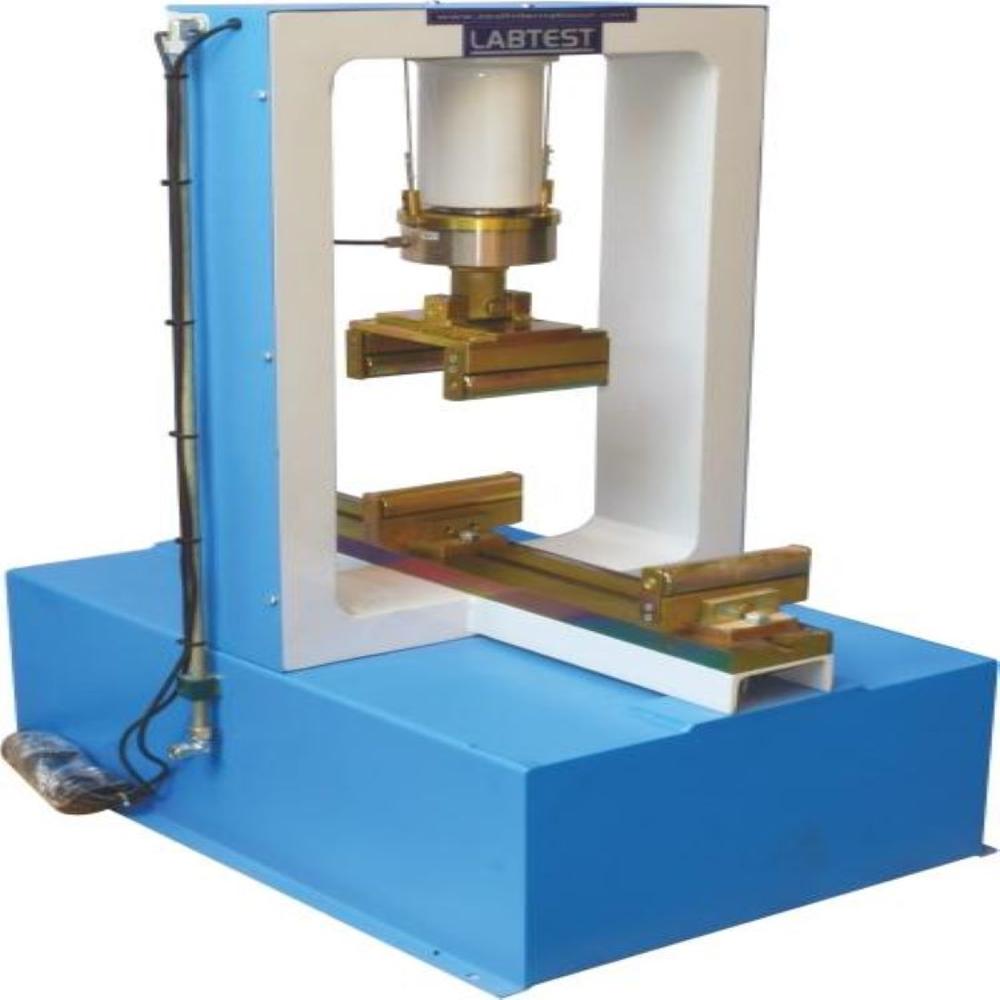

Automatic Flexure Testing Machine - 100 kN

Price 180000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial/Construction Material Testing

Equipment Type : Automatic Flexure Testing Machine

Capacity : 100 kN

Application : Measurement of Flexural Strength of Concrete Beams

Capping Set (Horizontal)

Price 7000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Cap torque and sealing strength test

Equipment Type : Horizontal Capping Set

Capacity : 1000 N

Application : Bottle Cap Sealing/Testing

Sand Absorption Cone And Tamper

Price 3000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory Testing of Aggregates

Equipment Type : Laboratory Test Apparatus

Capacity : 500 ml Cone Volume Approx.

Application : Determining the Specific Fine Quality of Sand (Fine Aggregate)

Structural Engineering Lab Equipment

Price 10000 INR / Number

Minimum Order Quantity : 1 Container

Usage : Universities, Research Labs, Material Testing

Equipment Type : Structural Engineering Lab Equipment

Capacity : 100 kN Maximum

Application : Testing strength of structural materials

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry