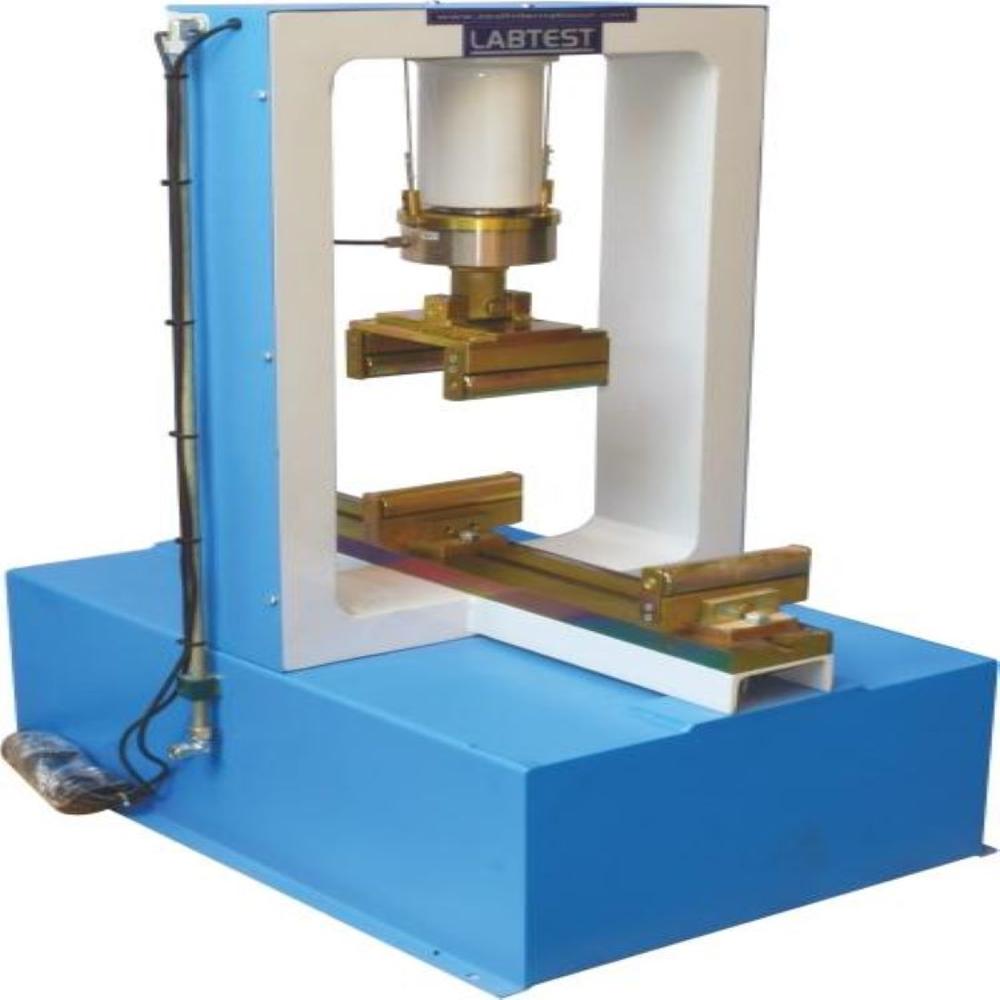

Automatic Flexure Testing Machine - 100 kN

Price 180000.0 INR/ Piece

Automatic Flexure Testing Machine - 100 kN Specification

- Humidity

- Suitable for ambient humidity 4585%

- Equipment Type

- Automatic Flexure Testing Machine

- Operating Voltage

- 230V AC

- Temperature

- Operating temperature 0C to 50C

- Resolution

- 0.01 kN

- Number of Specimens

- 1 at a time

- Display Type

- Digital LCD Display

- Features

- Microprocessor driven, programmable test cycles, overload protection, emergency stop

- Hardness

- Heavy-duty, rigid frame

- Measuring Range

- 0-100 kN

- Test Range

- 0100 kN

- Accuracy

- 1%

- Power Supply

- 230V AC, 50 Hz, Single Phase

- Max Height

- Approx. 700 mm

- Frequency

- 50 Hz

- Mounting Type

- Floor Mounted

- Automation Grade

- Automatic

- Application

- Measurement of Flexural Strength of Concrete Beams

- Response Time

- Instantaneous

- Port Size

- Standard Port for Specimen Placement

- Interface Type

- RS232/USB for Data Transfer

- Specimen Size

- Beam: 100 mm x 100 mm x 500 mm, 150 mm x 150 mm x 700 mm

- Usage

- Industrial/Construction Material Testing

- Capacity

- 100 kN

- Machine Weight

- Approx. 250 kg

- Test Speed

- 0.05 mm/min to 5.00 mm/min

- Test Width

- 150 mm

- Test Stroke

- Up to 120 mm

- Control Mode

- Automatic (Microprocessor Based Control)

- Oil Tank Capacity

- Approx. 10 Liters

- Standards Compliance

- IS 516, ASTM C78, EN 12390-5

- Data Storage

- Internal memory for up to 1000 test results

- Software Support

- PC-based data acquisition and reporting (optional)

- Language Support

- Multi-language firmware

- Frame Material

- High-quality steel construction with powder-coated finish

- Optional Accessories

- Printer interface, different specimen holding fixtures

- Loading System

- Hydraulic with servo-controlled actuator

- Calibration

- Supplied with calibration certificate

- Safety Features

- Emergency stop, overload protection, limit switches

Automatic Flexure Testing Machine - 100 kN Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- coimbatore

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- cotton box

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- Meghalaya, Manipur, Andhra Pradesh, Dadra and Nagar Haveli, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal, All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram

About Automatic Flexure Testing Machine - 100 kN

Specification:

TheLabtest Automatic Flexure Testing machineis designed perform flexural test on concrete beams, Transverse Test on kerbs and flagstones, indirect tensile tests on concrete and interlocking pavers. Labtest Automatic Flexure Testing Machine consist of three main parts.

Frame:

The versatile load frame is designed for minimum deflection at maximum load resulting in very high accuracy. The load frame is welded steel fabrication carrying the ram fitted to the upper crosshead. All frames have a single acting down stroking ram with over travel switch protection to shut the machine down should maximum ram travel be reached. The return of the ram is done by dead weight to get maximum accuracy on the load measurement. The load cell is used for load measurements.

The main characteristics are:

- Two capacity high stability welded assembly

- 75 and 100 mm piston stroke with safety limit switch

- Piston return by dead weight

- Accept all required accessories for mentioned standards

Data Acquisition & Control System (optional)

LCD graphics data acquisition and controls system is designed to control the machine and processing of data from load cells or pressure transducers installed on the compression machine frame. The easy to read LCD graphic display and touch-button data pad keys make the unit quick and straight forward to operate. All interaction with the measuring system is via the front control panel by using simple menu-driven procedures. The ergonomically designed indicator is contained in light alloy housing. The digital graphic display allows real time load vs time graph. At the end of the test cycle the results can be stored in the memory or downloaded to a PC in Labtest software. Dedicated software package is available for online data processing, database management and certificate printing. Safety features all Labtest flexural machines are fitted with:

- Max pressure valve to avoid machine overloading

- Ram travel switch to prevent excessive piston travel

Specifications:

| Capacity | kN | 100 |

| Class 1 range | kN | 10-100 |

| Resolution | 1/65.000 | |

| Ram travel | mm | 75 |

| Max. Vert. Test space | mm | 170 |

| Max. Horiz. Test space | mm | 450 |

| Power | W | 750 |

| Frame Dimensions | mm | 600 x 830 x 1140 |

| Weight | Kg. | 180 |

Advanced Automation and Safety

Engineered for industrial and construction material testing, the machine integrates microprocessor-driven automatic control and programmable test cycles, delivering consistent and accurate results. Essential safety features such as emergency stop, overload protection, and limit switches ensure operator safety and reliable test performance even in demanding environments.

Flexible Testing and Data Management

With a test range of 0-100 kN and adjustable speeds from 0.05 mm/min to 5.00 mm/min, users can perform tests according to strict standards. The system's internal memory stores up to 1000 test results and provides optional PC-based software support, enabling comprehensive data acquisition, analysis, and multi-language report generation. Specimen compatibility and accessories offer versatility for different beam sizes.

Built for Durability and Compliance

Manufactured with heavy-duty steel construction and a powder-coated finish, the equipment combines rigidity with long-term resistance to environmental factors. Certified calibration ensures test accuracy of 1%. The Automatic Flexure Testing Machine complies with IS 516, ASTM C78, and EN 12390-5 standards, making it ideal for both laboratory and on-site use.

FAQ's of Automatic Flexure Testing Machine - 100 kN:

Q: How does the Automatic Flexure Testing Machine ensure accurate flexural strength measurements?

A: Accuracy is achieved through a hydraulic loading system with a servo-controlled actuator, microprocessor-based automatic control, and certified calibration, delivering test results within 1% accuracy and a resolution of 0.01 kN.Q: What types and sizes of specimens can be tested using this machine?

A: The machine is designed for concrete beams of sizes 100 mm x 100 mm x 500 mm and 150 mm x 150 mm x 700 mm, accommodating one specimen at a time with a maximum capacity of 100 kN.Q: When is it advisable to use the PC-based data acquisition software?

A: PC-based data acquisition software is recommended when advanced reporting, data storage beyond the internal 1000-test capacity, or extended data analysis is required for compliance or research purposes.Q: Where can the Automatic Flexure Testing Machine be installed?

A: The equipment is suitable for installation in laboratories, quality control rooms, and construction sites, operating efficiently under ambient humidity (45-85%) and temperature conditions (0C to 50C).Q: What is the process for conducting a flexural strength test with this machine?

A: Operators mount the concrete specimen, select the desired test parameters on the automatic control panel, and initiate the test. The machine applies hydraulic load until beam failure, recording and displaying results instantly on the LCD screen.Q: How do built-in safety features benefit users during operation?

A: Safety mechanisms such as emergency stop buttons, overload protection, and limit switches protect operators from mechanical hazards, machine overloads, and accidental disruptions during testing cycles.Q: What optional accessories are available for enhancing the machine's capabilities?

A: Optional accessories include printer interfaces for hard copy reports and a range of specimen holding fixtures to extend compatibility with different testing requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

Plate Type CTM, Hand Operated

Price 40000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory Testing, R&D

Mounting Type : Table Top

Power Supply : Not Required (Manual Operation)

Accuracy : 1 mm

Flexure Testing Machine - Hand Operated

Price 150000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory and OnSite Material Testing

Mounting Type : Floor Mounted

Power Supply : Not Required (Manual Operation)

Accuracy : 1% of indicated load

Tamping Rod

Price 1000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Concrete testing

Mounting Type : Handheld

Accuracy : Precisionground to specification

Density Of Fresh and Hardened Concrete Testing Machine

Price 22000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory

Mounting Type : Floor Mounting

Power Supply : Electric

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry