Tamping Rod

Price 1000.0 INR/ Piece

Tamping Rod Specification

- Mounting Type

- Hand-held

- Max Height

- 600 mm (standard length)

- Equipment Type

- Tamping Rod

- Frequency

- Manual, as per test standard

- Features

- Smooth finish, corrosion resistant, hardened steel, rounded or hemispherical ends

- Hardness

- Hardened Steel (typically 55-60 HRC)

- Specimen Size

- Suitable for standard concrete cylinders and cubes

- Temperature

- Ambient

- Number of Specimens

- Single rod for use on multiple specimens

- Response Time

- Instantaneous manual operation

- Application

- For compacting concrete in cylinder moulds or cube moulds

- Accuracy

- Precision-ground to specification

- Humidity

- Up to Ambient Conditions

- Test Range

- Compaction of concrete specimens

- Automation Grade

- Manual

- Usage

- Concrete testing

- Machine Weight

- Approx. 1 kg

- Test Speed

- Manual operation

- Control Mode

- Manual

- Grip Type

- Easy grip for manual use

- Rod Diameter

- 16 mm (standard), other sizes as per IS:10086/IS:516

- Surface Finish

- Bright polished

- Corrosion Resistance

- Yes, rust-proof finish

- Length Tolerance

- ±1 mm

- Color

- Metallic/Silver

- Packing

- Individually packed

- End Type

- Rounded/Hemispherical at one end

- Storage

- Comes with protective sleeve or pouch

- Rod Material

- Hard drawn steel rod

Tamping Rod Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- COIMBATORE

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- COTTON BOX

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- East India, All India, South India, Central India, West India, North India, Gujarat, Karnataka, Kerala, Mizoram, Lakshadweep, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Meghalaya, Madhya Pradesh, Maharashtra, Telangana, Tripura, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Tamping Rod

Specification:

This is used for compacting concrete into cube moulds. This rod is made of steel it is 16 mm dia., 600 mm in length and rounded at both ends.A tamping rod used in concrete testing is typically a steel rod, 16mm (5/8 inch) in diameter and 600mm (24 inches) long, with one end rounded or hemispherical.These rods are used for compacting concrete samples in various tests like the slump test and cube test.

- Material:Steel.

- Diameter:16 mm (5/8 inch).

- Length:600 mm (24 inches).

- End Shape:One end is rounded or hemispherical.

- Additional Features:May be zinc/nickel plated for corrosion resistance.

- Standards:Often conform to standards like BS 1881-108 and EN 12390-2 for cube tests.

- Usage:Specifically designed for compacting concrete samples in slump tests, cube tests, and other concrete workability tests.

Precision and Durability

Crafted from hard drawn steel, the tamping rod is precision-ground to meet exacting specifications. Its hardened construction achieves a typical hardness of 55-60 HRC, ensuring long-term durability and resistance to corrosion. The bright polished surface contributes to ease of cleaning and optimal laboratory hygiene.

Versatile Concrete Testing

Suitable for compacting concrete in both cylinder and cube moulds, this tamper meets the demands of varied laboratory and field environments. Its ergonomic grip guarantees comfortable and efficient manual operation, with instant response time and accurate preparation of specimens for further testing.

Protection and Ease of Use

Each tamping rod is supplied individually packed, complete with a protective sleeve or pouch for safe storage and transport. The rounded or hemispherical end enhances compaction uniformity, and its metallic silver finish ensures high visual clarity during use. The rod is designed for single-hand operation and stable control.

FAQ's of Tamping Rod:

Q: How do I use the tamping rod for concrete specimen compaction?

A: To use the tamping rod, manually insert it into the concrete specimen within a cylinder or cube mould and apply repeated, even strokes with the rounded or hemispherical end. This process ensures uniform compaction and eliminates air pockets in the concrete for reliable test results.Q: What standards do the tamping rods comply with?

A: The tamping rods are manufactured according to IS:10086 and IS:516 standards, ensuring compatibility with standardized concrete testing protocols in laboratories across India.Q: When should a tamping rod be used during concrete sampling?

A: The tamping rod is used during the specimen preparation phase, before curing begins, to thoroughly compact freshly mixed concrete within test moulds prior to strength or durability assessment.Q: Where is this tamping rod typically utilized?

A: This equipment is primarily used in material testing laboratories, construction sites, and quality control facilities for accurate compaction of concrete specimens during routine testing.Q: What are the benefits of a hardened steel tamping rod with corrosion resistance?

A: A hardened steel rod offers superior durability, with a rust-proof finish that maintains the rod's integrity in humid or reactive environments. This ensures consistent performance and extends equipment lifespan.Q: Can the tamping rod be used for both cubes and cylinders?

A: Yes, the rod is suitable for use with standard concrete cube and cylinder specimens, as specified by relevant testing standards, providing versatility for various types of concrete tests.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

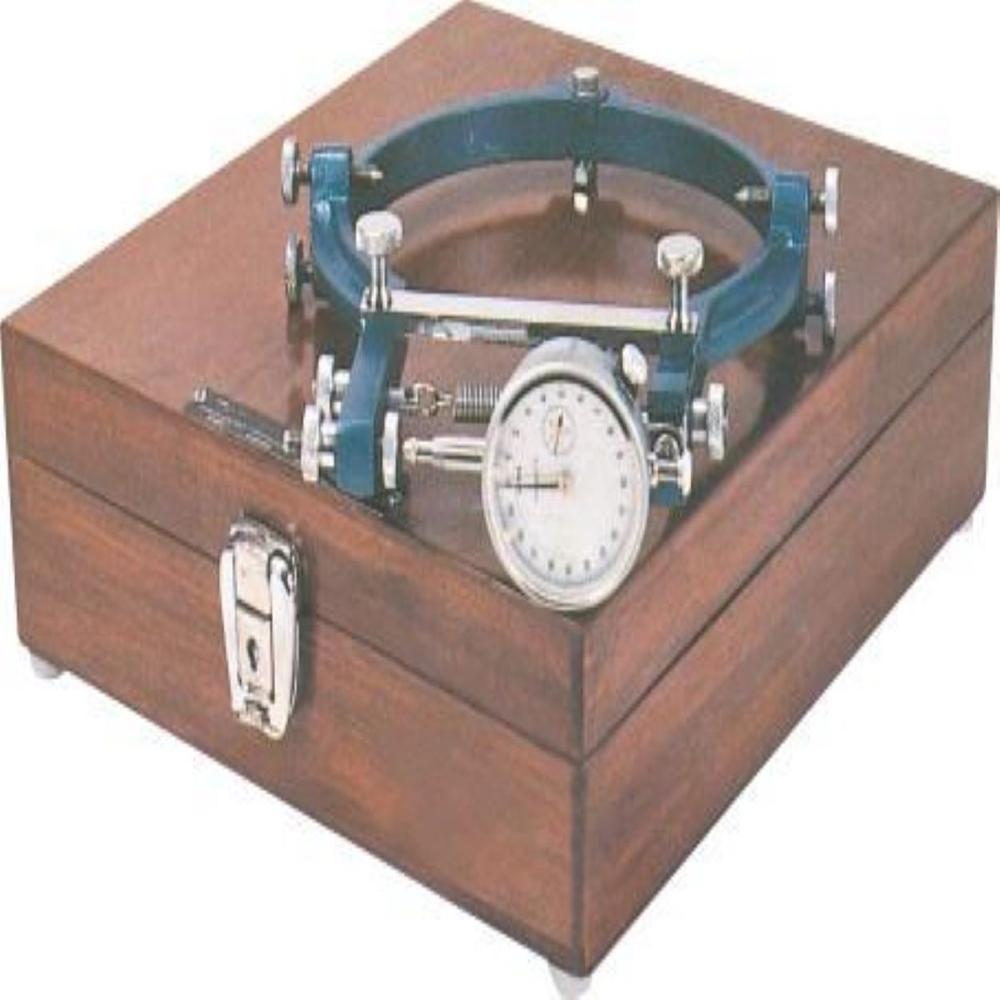

Lateral Extensometer

Price 15000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory/Material testing

Power Supply : Not required (mechanical)

Features : Simple design, robust construction, portable

Mounting Type : Mechanical clampon

Gun For Mould

Price 1000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial and workshop use for moulds

Power Supply : None (manual)

Features : Lightweight, ergonomic, easy to use, corrosion resistant body

Mounting Type : Handheld

Stopper For Plastic Cube Mould

Price 200.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Used in construction lab testing

Features : Reusable, easy fitting, durable plastic, leak proof

Mounting Type : Press fit

Melting Pot

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : laboratory

Power Supply : Electric

Mounting Type : Floor Mounting

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry