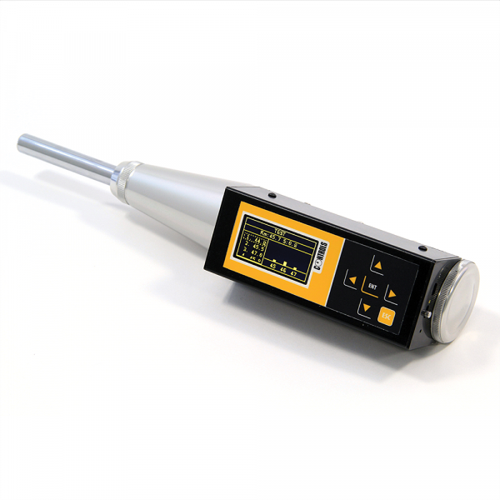

Digital Test Hammer

Price 98000 INR/ Piece

Digital Test Hammer Specification

- Power Supply

- Battery

- Usage

- Laboratory

- Operate Method

- Automatic

- Color

- Blue

- Display Type

- LED Display

- Material

- Plastic

Digital Test Hammer Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Chennai

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 2 Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Digital Test Hammer

This digital concrete test hammer, microprocessor operated, entirely designed and manufactured with advanced technology, performs basic concrete testing with continuous automatic recording of all parameters in accordance with EN 12504-2 Specifications, register and process data and then transfer them to a PC The unit consists of the standard mechanical model, but equipped with an electronic transducer that measures the rebound values and supplies automatically the results on a graphic display.

During test performing:

- Shows index value

- Shows average index value

- Allows to select measuring system in MpA or Psi

- Shows numbers of performed rebounds

- Shows date and time

- Identifies tested element

- Identifies automatically and shows rebound angle

- Shows battery life

Main features:

- Possibility to store, display on graphic LCD 64x124 and download data to PC over 20000 tests

- Automatic statistical processing and readings

- Automatic conversion of rebound index to equivalent compression strength in psi, N/mm2, kg/cm2

- High accuracy and resolution

- Supplied complete with data transfer software, data transfer cable RS232, battery charger, abrasive stone, carrying case

- The digital test hammer is suitable to be connected to the Ultrasonic Tester high performance model ZI 2071-B for combined ultrasonic and rebound tests with automatic data acquisition, processing and store of the results

Additional Information:

- Item Code: ZI-2069B

- Port of Dispatch: New Delhi Airport per ICD New Delhi

- Production Capacity: 5-6 machines per month

- Delivery Time: 7-10 Days

- Packaging Details: CARDBOARD PACK

Efficient Automated Testing

With an automatic operating method, the Digital Test Hammer streamlines laboratory workflows by reducing manual intervention. This leads to faster, more consistent testing outcomes, allowing laboratories to process more samples with reduced chances of human error.

Clear and Reliable LED Display

The device features a bright LED display, which delivers immediate and easy-to-read results. Users benefit from enhanced visibility, even in low-light laboratory conditions, ensuring data is captured accurately during each test.

FAQs of Digital Test Hammer:

Q: How does the Digital Test Hammer operate in laboratory environments?

A: The device operates automatically, allowing users to conduct tests without manual triggering. Its battery power and LED display provide efficient and error-free material strength assessments in laboratory settings.Q: What materials is the Digital Test Hammer made from and what are its color options?

A: The test hammer is constructed from high-quality plastic, designed for durability and ease of handling. Its standard color is blue, which is widely recognizable in laboratory environments.Q: When is it recommended to use the Digital Test Hammer?

A: It is best utilized during quality control procedures, routine laboratory testing, and whenever precise material strength evaluation is required, ensuring reliability and consistent results over multiple testing cycles.Q: Where can the Digital Test Hammer be sourced in India?

A: This device is available through numerous channels including dealers, distributors, exporters, manufacturers, suppliers, and other authorized trading entities nationwide.Q: What is the process for using the Digital Test Hammer?

A: First, power the device using its battery, position it on the material to be tested, and initiate the automatic test. Results are immediately displayed on the LED screen for straightforward data recording.Q: How is the usage of the Digital Test Hammer beneficial compared to manual alternatives?

A: The automated operation minimizes user error, speeds up testing, and the LED display simplifies result interpretation, making it markedly more efficient and accurate than traditional manual methods.Q: What industries benefit most from the Digital Test Hammer?

A: Primarily laboratories in India aiming for precise material evaluation, but also manufacturers, traders, dealers, and fabricators engaged in quality control and material testing processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

Vibrating Table

Price 24000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Color : Grey

Usage : Laboratory

Flexure Testing Machine

Price 110000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Color : White

Usage : laboratory

Digital Concrete Test Hammer with Microprocessor

Price 30000.0 INR / Piece

Minimum Order Quantity : 1 Piece

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry