Vibrating Table

Price 24000 INR/ Piece

Vibrating Table Specification

- Material

- Mild Steel

- Color

- Grey

- Usage

- Laboratory

- Power Supply

- Electric

- Mounting Type

- Floor Mounting

- Capacity

- 140 Kg

Vibrating Table Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Chennai

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 2 Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Vibrating Table

Robust Laboratory Performance

Engineered for demanding laboratory environments, this grey vibrating table boasts a 140 kg capacity and is constructed from mild steel. The floor-mounting feature ensures stability during operation, while its electric power supply provides consistent results. Perfect for laboratories seeking efficient material compaction and testing solutions.

Widely Available Across India

As a product supplied and distributed by manufacturers, dealers, exporters, and other vendors, this laboratory vibrating table is easily accessible throughout India. Whether you are a retailer, supplier, or end-user, sourcing this reliable equipment is straightforward from various trusted sources.

FAQs of Vibrating Table:

Q: How is the vibrating table installed in a laboratory setting?

A: The vibrating table is designed for floor mounting, ensuring a stable and secure setup. Install it on a flat, sturdy surface and follow the manufacturers guidelines for anchoring the unit to the floor. Proper installation maximizes performance and safety during operation.Q: What materials can be processed using this vibrating table?

A: This table supports a capacity of up to 140 kg and is ideal for compacting, settling, and testing various laboratory samples. It is suitable for use with powdery, granular, or small aggregate materials common in scientific experiments.Q: When should I use a vibrating table in my laboratory processes?

A: A vibrating table is needed when you require uniform compaction or settling of samples during testing procedures. It is often used in material testing, quality control, and research applications where eliminating air pockets or ensuring even distribution is essential.Q: Where can I purchase or source this vibrating table in India?

A: You can acquire this vibrating table from manufacturers, dealers, exporters, suppliers, retailers, and wholesalers throughout India. Many distributors and traders offer this product for laboratory use, providing options for both large and small orders.Q: What is the process for operating the vibrating table?

A: After installation, place your sample on the table and securely fasten it if needed. Turn on the power supply and set the desired vibration intensity. Monitor the sample during operation to achieve the intended compaction or settling, then turn off the unit after use.Q: How does using a vibrating table benefit laboratory testing?

A: Using a vibrating table provides consistent, uniform compaction and settlement of materials, leading to more accurate and reliable test results. This helps enhance the quality and repeatability of laboratory analyses or material preparation steps.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

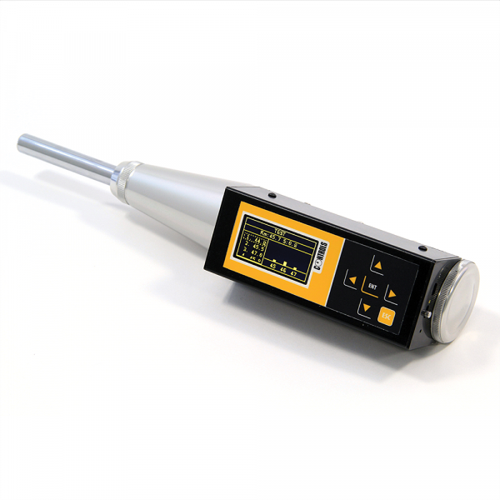

Digital Concrete Test Hammer with Microprocessor

Price 30000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Mounting Type : Handheld

Usage : Field and laboratory testing

Power Supply : Rechargeable lithium battery

Display Type : Backlit LCD Digital Display

Slump Cone Plastic

Price 1900.0 INR / Piece

Minimum Order Quantity : 1 Piece

Mounting Type : Portable, Free Stand

Usage : Slump Test for Concrete

Power Supply : Not Required (Manual Operation)

Display Type : Visual (No Digital Display)

Bulk Density Measuring Cylinder

Price 10000 INR / Bale

Minimum Order Quantity : 1 Bale

Mounting Type : Benchtop

Usage : Laboratory/Bulk Density Testing

Display Type : Graduated Glass Scale

Crack Microscope

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Mounting Type : Floor Mounting

Usage : Laboratory

Power Supply : Manual

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry