Sieve Shaker

Price 22000 INR/ Piece

Sieve Shaker Specification

- Mounting Type

- Floor Mounting

- Application

- Laboratory,Industrial

- Operate Method

- Automatic

- Color

- Silver

- Power

- 230 Volt (v)

- Material

- Steel

- Power Supply

- Electric

Sieve Shaker Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- Piece

- Delivery Time

- Days

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Pondicherry, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, South India, North India, East India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Andhra Pradesh, Kerala, Central India, Chhattisgarh, All India

About Sieve Shaker

Specifications:

Carries upto 7 sieves of 150mm or 200mm diameter. The shaker is driven by a 1/4 h.p. motor through a reduction gear immersed in oil. The sieve table dies not rotate but is inclined from the vertical axis and the direction of inclination changes progressively in clockwise direction. If the stop-pin below the table is removed, the shaker can have a rotary motion. In addition to this gyratory motion of the table, there is an upward & downward movement ensuring that each square cm of the sieve is utilised. A pair of rods and a holder are supplied. The holder can be fixed on the top of the upper most sieve, and thus the sieve set is firmly held. Suitable for operation form 230 volts, 50 cycles phase, A.C. supply. Nett weight appprox. 77 kgs. Available in digital display model also.

Salient Features

- Accessories: Adaptor for 30 cm diameter sieves. Time switch 0-60 mins in 5 mins graduation.

-

- Manufactured in Chennai

- Dealership in Chennai

Built for Durability and Precision

Manufactured from high-quality steel, the Sieve Shaker stands out for its sturdy construction and exceptional longevity. Its precise design ensures accurate, repeatable results in laboratory and industrial environments, meeting the demands of rigorous daily usage.

Automatic Operation for Effortless Testing

This Sieve Shaker operates automatically, minimizing manual intervention and reducing user fatigue. Simply set your preferred parameters, and the machine takes care of the entire process, ensuring uniform agitation necessary for effective particle separation.

Widely Accessible Across India

With a strong network of dealers, distributors, and other suppliers, the Sieve Shaker is readily available throughout India. Whether your business is a laboratory or a large-scale industrial facility, you can easily procure this essential equipment.

FAQs of Sieve Shaker:

Q: How does the automatic Sieve Shaker simplify laboratory testing?

A: The Sieve Shaker automates the sieving process, ensuring consistent agitation and accurate separation of materials based on particle size, while minimizing manual labor and human error.Q: What materials are used in the construction of the Sieve Shaker?

A: The Sieve Shaker is built using high-grade steel, providing strength, durability, and resistance to corrosion, which is ideal for demanding laboratory and industrial environments.Q: When should I use a Sieve Shaker in my industrial or laboratory process?

A: Use the Sieve Shaker whenever you need reliable particle size analysis, quality control, or material quality assessment, particularly in situations where accurate sieving is crucial.Q: Where can I purchase the Sieve Shaker in India?

A: The Sieve Shaker can be sourced across India through a comprehensive network of dealers, distributors, exporters, fabricators, manufacturers, producers, retailers, suppliers, traders, and wholesalers.Q: What are the benefits of using an electric-powered, floor-mounted Sieve Shaker?

A: An electric-powered, floor-mounted design ensures stability, efficient energy use, and streamlined operation, accommodating large sample volumes and providing hassle-free, continuous work processes.Q: How do I operate the Sieve Shaker, and what makes it user-friendly?

A: To operate, simply place your sieves and samples, select the appropriate settings, and start the automatic cycle. Its intuitive controls and automatic operation make it accessible to both new and experienced users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Soil Testing Equipment Category

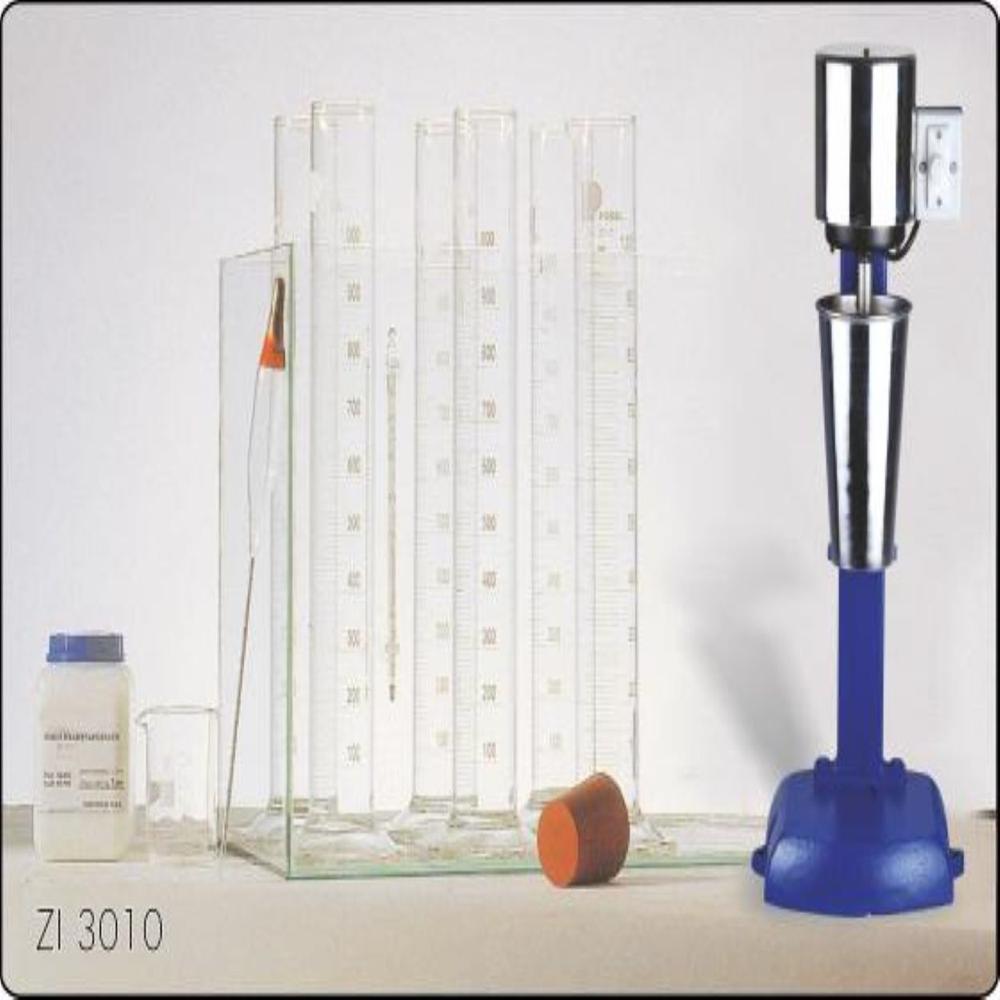

Particle Size Sedimentation (Hydrometer Method)

Price 15000.0 INR / Piece

Minimum Order Quantity : 1 Piece

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry