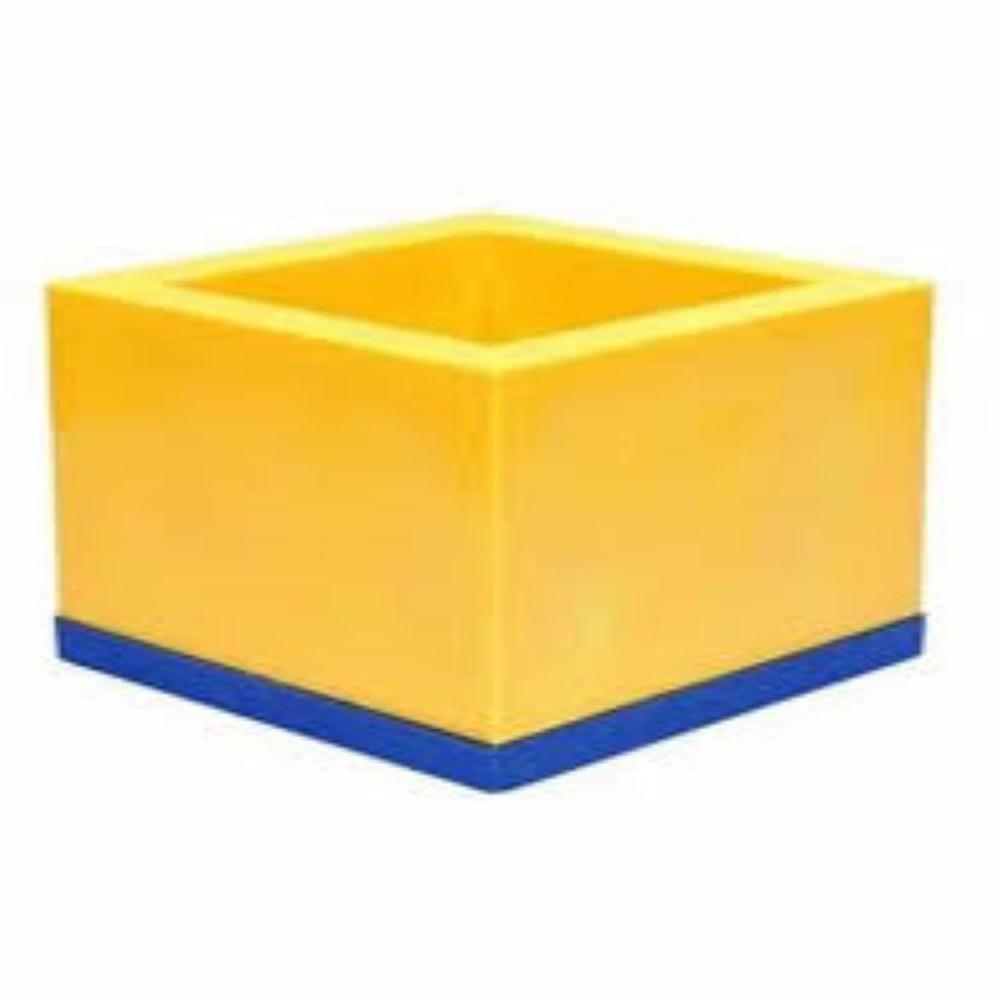

50mm Cube Mould, Plastic

Price 600.0 INR/ Piece

50mm Cube Mould, Plastic Specification

- Mold Base

- Plastic

- Cavity

- Single (1)

- Molding Material

- Polypropylene (PP)

- Life Span

- Reusable, suitable for repetitive testing

- Shaping Mode

- Injection Moulding

- Material

- High-impact Plastic

- Tolerance

- 0.2 mm

- Mould Weight

- Approx. 250 g

- Mould Life

- Over 1000 cycles

- Surface Finish

- Smooth, non-adhesive

- Use

- Cement, concrete, and mortar testing

- Temperature Range

- 0°C to 60°C

- Internal Size (Cube)

- 50 mm x 50 mm x 50 mm

- Compliance

- IS:10086, ASTM C109, EN 196-1 standards

- Markings

- Moulded volume details for identification

- Color

- Blue (may vary by batch)

- Demoulding Feature

- Easy split, self-aligning

- Water Absorption

- Resistant

50mm Cube Mould, Plastic Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- COIMBATORE

- Average Load Time

- Approx. 1 minute

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- COTTON BOX

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- South India, Central India, East India, Gujarat, Karnataka, Meghalaya, Manipur, Andhra Pradesh, Goa, Jharkhand, Odisha, Punjab, Bihar, Chandigarh, West India, North India, Nagaland, Rajasthan, West Bengal, All India, Kerala, Lakshadweep, Mizoram, Delhi, Dadra and Nagar Haveli, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Daman and Diu, Assam, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand

About 50mm Cube Mould, Plastic

Specification:

This high-density polyethylene three-gang plastic mould for 50 mm cubes strips and reassembles easily. Set comes complete with tamper and mould top. 3 gang plastic cube mould offers substantial cost savings in comparison with traditional cast iron cube moulds.

Standards: Specification: This high-density polyethylene three-gang plastic mould for 50 mm cubes strips and reassembles easily. Set comes complete with tamper and mould top. 3 gang plastic cube mould offers substantial cost savings in comparison with traditional cast iron cube moulds.

Precision Engineering for Laboratory Reliability

Crafted to deliver accuracy, this cube mould offers tight tolerances of 0.2 mm, critical for consistent test replication. Its smooth, non-adhesive surface finish guarantees effortless cube removal with no damage, preserving test specimen integrity during cement, mortar, and concrete evaluations.

Robust Construction and Long-Term Use

Made from high-impact polypropylene through injection moulding, this mould provides exceptional durability. Water-resistant and capable of enduring rigorous temperature swings, it is ideal for laboratories and construction sites that demand repeated, reliable sample preparation and measurement.

FAQ's of 50mm Cube Mould, Plastic:

Q: How is the 50mm Cube Mould used for material testing?

A: This mould is filled with cement, concrete, or mortar mixtures, compacted to remove air voids, and then cured as per test protocols. After setting, the specimen is demoulded for rigorous compressive or strength testing, ensuring accurate and standard-compliant evaluations.Q: What makes the mould easy to demould after sample curing?

A: The easy split, self-aligning design combined with a smooth, non-adhesive surface finish allows for straightforward demoulding. This minimizes specimen damage and speeds up laboratory workflow, as the cube comes out cleanly with minimal effort.Q: When should I replace the 50mm Cube Mould?

A: Though designed for over 1000 testing cycles, replace the mould if you notice significant wear, deformation, or damage that may affect sample shape, dimension accuracy, or test results. Routine inspection is advised for optimal performance.Q: Where can this cube mould be used effectively?

A: The mould is suitable for use in construction laboratories, quality control units at building sites, research institutions, and industrial plants that routinely conduct cement, mortar, or concrete testing.Q: What standards does this mould comply with?

A: It meets IS:10086, ASTM C109, and EN 196-1 specifications, ensuring that test results are both accurate and globally recognized in cementitious material testing applications.Q: How does the polypropylene construction benefit users?

A: Polypropylene is lightweight yet highly durable, making the mould easy to handle and resistant to cracking, absorption, and temperature swings. This translates to less maintenance, longer service life, and lower replacement costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Moulding Products Category

Plastic Beam Mould

Price 2500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, HighDensity Polyethylene (HDPE)

Life Span : 35 years with proper care

Three Gang Cube Mould

Price 1200 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Plastic

Life Span : Longlife Span

Color : Blue

Usage : Industrial

CBR Mould

Price 1500 INR / Bale

Minimum Order Quantity : 1 Billions Of Unit

Material : Other, Mild Steel

Life Span : 57 years

DLC Vibrating Hammer For Concrete Mould

Price 27000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Mild Steel

Color : Black Blue

Usage : Industrial

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry