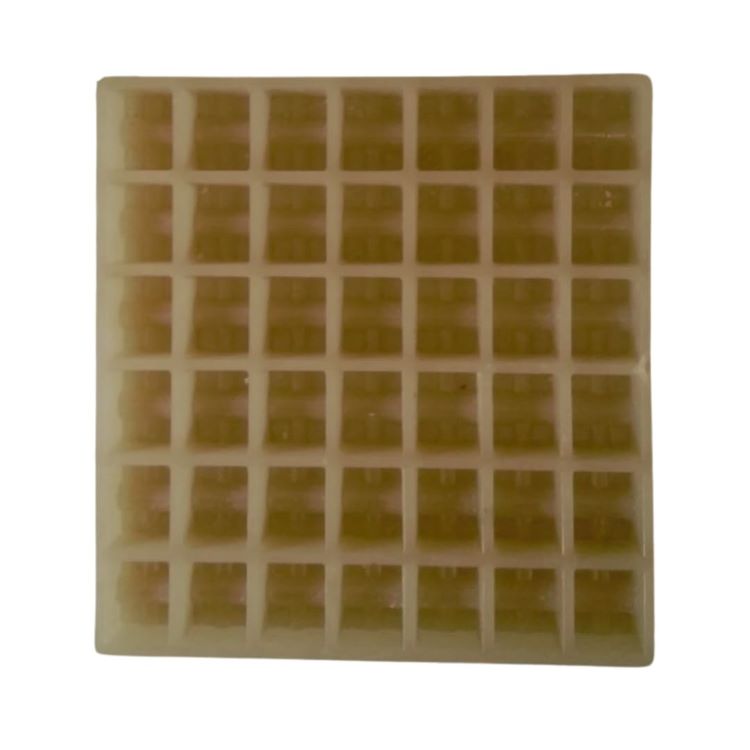

Plastic Beam Mould

Price 2500.0 INR/ Piece

Plastic Beam Mould Specification

- Cavity

- Single

- Molding Material

- Plastic Polymer

- Mold Base

- Durable Plastic (Heavy Duty Construction)

- Life Span

- 3-5 years with proper care

- Shaping Mode

- Extrusion Mould

- Material

- High-Density Polyethylene (HDPE)

- Tolerance

- 1 mm

- Mould Weight

- Approx. 3.5 kg

- Mould Life

- Up to 1000 cycles

- End Type

- Removable End Plates for Easy Demoulding

- Surface Finish

- Smooth, Non-Adherent

- Application

- Concrete Beam Casting

- Water Tightness

- Leak Proof Design

- Beam Size

- 150 mm x 150 mm x 700 mm (Standard)

- Resistant To

- Chemicals, Corrosive Environments

- Color

- Blue

- Usage

- Civil Engineering Lab & Material Testing

- Easy Cleaning

- Yes

Plastic Beam Mould Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- coimbatore

- Average Load Time

- Approx. 5-10 minutes

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- cotton box

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- All India, Uttar Pradesh, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttarakhand, West Bengal

About Plastic Beam Mould

Specification:

Zeal International is the first Indian manufacturer of Plastic & Polyurethane Beam Mould.

ZI 2029-A 100 x 100 x 500 mm Plastic Beam Mould 2.5 KG

ZI 2029-B 100 x 100 x 500 mm Polyurethane Beam Mould 2.5 KG

Zeal International also manufactures complete range of concrete moulds for construction industry. The list of available concrete moulds is given below:

Precision and Durability for Accurate Concrete Beam Casting

The Plastic Beam Mould has been designed to deliver consistent, precise shaped beams for various civil engineering laboratory tests. Its robust HDPE construction ensures resistance to corrosion and chemicals, while offering a 1 mm dimensional tolerance. Ideal for repeated testing, this mould supports up to 1000 cycles with minimal maintenance, delivering reliable results every time.

Effortless Cleaning and Demoulding

Thanks to a smooth, non-adherent surface and removable end plates, cleaning and demoulding are simplified. After beam curing, users can quickly detach the end plates for trouble-free removal. The leak-proof construction prevents slurry leakage during pouring and curing, maintaining specimen integrity and laboratory cleanliness.

FAQ's of Plastic Beam Mould:

Q: How is the Plastic Beam Mould used in a civil engineering laboratory?

A: The mould is used for casting concrete beams during material testing and structural analysis. Its standard size lets users prepare specimens for strength and durability assessments. The removable end plates facilitate easy demoulding once curing is complete.Q: What benefits does the leak-proof design offer during the casting process?

A: The leak-proof construction ensures that concrete or slurry stays contained within the mould, preventing leakage that could compromise beam integrity and test accuracy. This feature supports reliable results and maintains laboratory cleanliness.Q: When should the mould be cleaned, and how easy is the cleaning process?

A: The mould should be cleaned after each casting cycle. Its smooth, non-adherent surface makes it easy to wash off residual concrete, ensuring efficient preparation for the next use and supporting mould longevity.Q: Where can I purchase the Plastic Beam Mould in India?

A: This mould is available through various dealers, distributors, exporters, manufacturers, suppliers, retailers, and wholesalers throughout India. For bulk orders or custom requirements, contacting a fabricator or producer is recommended.Q: What materials is the mould made of, and why is HDPE chosen?

A: The mould is crafted from high-density polyethylene (HDPE), a robust plastic polymer known for resistance to abrasives, chemicals, and corrosion. HDPE provides durability for repeated casting cycles and ease of maintenance.Q: How long does the Plastic Beam Mould last under regular usage?

A: With proper care and usage, the mould can handle up to 1000 casting cycles, offering a typical lifespan of 3-5 years, making it a cost-effective choice for frequent testing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Moulding Products Category

Briquette Mould (Single)

Price 3000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, High Grade Steel

Life Span : 57 years under normal working conditions

Cube Mould

Price 700 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Metal

Life Span : Longlife Span

Color : Blue

Size : 15 cm

Beam Mould

Price 3800 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Mild Steel

Life Span : Longlife Span

Color : Blue

Size : 100 mm x 100 mm x 500 mm

Plastic Cube Mould

Price 700 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Plastic

Life Span : Longlife Span

Color : Black Yellow

Size : Standard

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry