Ring & Ball Apparatus (Semi Automatic)

Ring & Ball Apparatus (Semi Automatic) Specification

- Interface Type

- Push Button/Manual Control

- Humidity

- Ambient

- Max Height

- 350 mm

- Test Range

- 30C - 180C (Melting Point Determination)

- Temperature

- Room Temperature to 200C

- Resolution

- 0.1C

- Accuracy

- 0.5C

- Display Type

- Digital LED

- Automation Grade

- Semi-Automatic

- Equipment Type

- Ring & Ball Apparatus

- Measuring Range

- 30C to 180C

- Operating Voltage

- 220V AC

- Port Size

- Standard Laboratory Size

- Application

- Determination of Softening Point of Bitumen, Pitch, Tar, Wax, Resins

- Response Time

- Instantaneous

- Specimen Size

- According to ASTM D36/IS 1205

- Number of Specimens

- 2 simultaneous rings

- Features

- Temperature Controller, Stirrer, Digital Display, Audible Alarm

- Frequency

- 50 Hz

- Power Supply

- 220V AC, 50 Hz

- Mounting Type

- Benchtop

- Usage

- Laboratory Testing

- Capacity

- Dual position

- Machine Weight

- Approx. 8 Kg

- Test Speed

- Semi-Automatic (Manual Ball Placement with Automatic Heating)

- Test Width

- Standard Width 100 mm

- Control Mode

- Semi-Automatic

- Number of Rings

- 2

- Timer

- Digital timer for process control

- Accessories Included

- Brass rings, steel balls, sample holder, glassware

- Standard Conformance

- ASTM D36, IS 1205

- Bath Type

- Heat-resistant glass bath

- Alarm System

- Integrated audible alarm at softening point

- Ball Material

- Steel balls

- Heating Method

- Microprocessor-based heating unit with digital temperature control

- Calibration

- Factory calibrated and adjustable

- Ring Material

- Brass/Solid metal

- Ambient Conditions

- Temperature 5°C - 40°C, relative humidity up to 80%

- Stirring Mechanism

- Magnetic or electric stirrer for uniform heating

- Safety Features

- Thermal overload protection

Ring & Ball Apparatus (Semi Automatic) Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- coimbatore

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- cotton box

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- Punjab, Delhi, Dadra and Nagar Haveli, North India, East India, Kerala, All India, Daman and Diu, Andaman and Nicobar Islands, Arunachal Pradesh, Jammu and Kashmir, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal, South India, Central India, West India, Gujarat, Karnataka, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Goa, Jharkhand, Odisha, Assam, Chhattisgarh, Haryana, Himachal Pradesh, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan

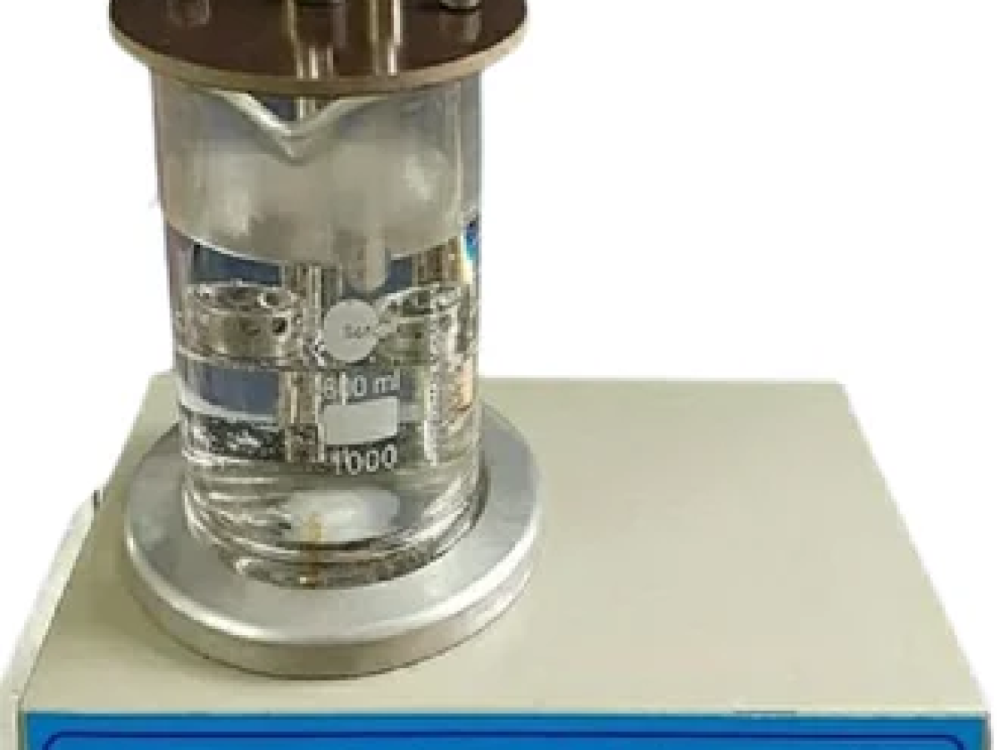

About Ring & Ball Apparatus (Semi Automatic)

Standards:IS:1205, ASTM D 36, E 28, IP 198, IP 58, AASHTO T53, BS:2000, EN 1427

Specification:

For determining the temperature at which a sample of bituminous material loaded by a 9.5 mm dia steel ball, drops a specified distance when heated under specified conditions.

Ring and Ball Apparatus

The new design of Ring and Ball Apparatus is compact user friendly and has better aesthetics. It has magnetic stirrer with heating facility and digital display of temperature, the heating can be adjusted through knob. Suitable for operation on 220 V, 50 Hz, single phase, AC supply. Each unit is supplied with a bath of heat resistant glass and the following:

ZI 4003-A Tapered Rings : 2 Nos.

ZI 4003-B Ball Centering Guide : 2 Nos.

ZI 4003-C Steel Balls of 9.5 mm dia : 2 Nos.

ZI 4003-D Ring Holder : 1 No.

ZI 4003-E Electric Heater (Hot Plate) : 1 Nos

Advanced Temperature Control

Utilizing a microprocessor-based heating unit, the apparatus offers digital temperature control and instant response time. The user can set desired temperatures with high accuracy (0.5C) and observe real-time readings on the digital LED display. This technology enhances the precision required for softening point determination in materials.

Uniform Heating for Reliable Results

The integrated magnetic or electric stirrer ensures even heat distribution within the heat-resistant glass bath. This consistent and uniform heating process minimizes thermal gradients, providing reproducible results and maintaining testing reliability for laboratory measurements.

Enhanced Safety and Accuracy

Safety features include thermal overload protection and an integrated audible alarm that activates upon reaching the softening point. The apparatus is factory calibrated and allows for digital adjustment, ensuring continued accuracy and safe operation during bitumen, tar, or resin testing.

FAQ's of Ring & Ball Apparatus (Semi Automatic):

Q: How does the Ring & Ball Apparatus ensure uniform heating during testing?

A: The apparatus features a heat-resistant glass bath equipped with a magnetic or electric stirrer, which circulates the heated liquid and guarantees consistent thermal distribution throughout the sample for accurate softening point measurements.Q: What materials can be tested with this semi-automatic Ring & Ball Apparatus?

A: It is suitable for determining the softening point of a variety of substances, including bitumen, pitch, tar, wax, and resins, following ASTM D36 and IS 1205 standards.Q: When should the audible alarm be expected to sound during an experiment?

A: The integrated audible alarm is programmed to activate automatically when the softening point of the tested material is reached, allowing the operator to promptly note the result without manual monitoring.Q: Where can this apparatus be installed for laboratory testing?

A: Designed for benchtop mounting, the apparatus fits standard laboratory setups, making it ideal for use by manufacturers, suppliers, traders, or research laboratories across India.Q: What is the process for conducting a test using this equipment?

A: After placing specimens in the brass rings and steel balls as per standard specifications, the user sets the desired temperature range and starts the heating cycle. The semi-automatic system manages heating and monitoring, while the operator manually positions the balls, all controlled via push-button/manual interface.Q: How does factory calibration benefit laboratory users?

A: Factory calibration ensures that each apparatus is preset for accuracy; however, users retain the ability to adjust calibration when required, providing reliable results and supporting compliance with testing standards.Q: What are the main advantages of using the semi-automatic model over manual units?

A: The semi-automatic apparatus streamlines heating control, increases accuracy with digital features, reduces operator error with alarms, and delivers dual simultaneous specimen testing, making laboratory processes more efficient and trustworthy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Soil Testing Equipment Category

Auger Posthole Type

Price 2500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Used for digging post holes in various soil conditions

Power Supply : No external power required (manual)

Reflux Extractor

Price 4500 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory

Color : White Silver

Material : Stainless Steel

Power Supply : Electric

Shrinkage Limit Set

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory

Color : Black

Material : Brass, Plastic, Steel

Power Supply : Manual

Moisture Tin

Price 150 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : laboratory

Color : Sliver

Material : GI

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry