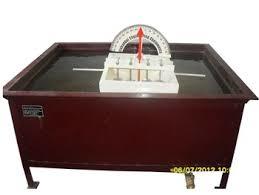

Francis Turbine Test Rig

Price 6000 INR/ Piece

Francis Turbine Test Rig Specification

- Usage

- Laboratory

- Power Supply

- Electric

- Color

- Blue Grey

- Material

- Mild Steel

- Mounting Type

- Floor Mounting

- Operate Method

- Automatic

Francis Turbine Test Rig Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Chennai

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Delivery Time

- 2 Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Tripura, Manipur, Pondicherry, Uttarakhand, Dadra and Nagar Haveli, Lakshadweep, South India, East India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Delhi, Daman and Diu, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Maharashtra, Mizoram, Meghalaya, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Haryana, Uttar Pradesh, Gujarat, West Bengal, Madhya Pradesh, North India, Andhra Pradesh, Central India, Chhattisgarh, All India

About Francis Turbine Test Rig

Francis Turbine Test Rig

Francis turbine is a reaction turbine which was developed by an English born American engineer Sir J.B Francis. the water enter the turbine though the outer periphery of the runner in The redial direction & leaves the runner in axial direction & hence it is called a mixed flow turbine As the water flow to the the runner a part of pressure energy goes on changing in to kinetic energy. Thus the water though the runner is completely enclosed in a air tight casing & the casing & runner is always full of water.

Robust Construction and Design

Built from high-quality mild steel, the Francis Turbine Test Rig provides durability and stability, essential for laboratory experiments. Its blue-grey finish lends a modern appearance while resisting corrosion and wear, ensuring long-term use in demanding academic or research settings.

Effortless Automatic Operation

With an integrated automatic operating system, users can easily conduct turbine performance experiments without complex manual intervention. This feature streamlines workflow, reduces preparation time, and ensures precise control during each test cycle.

Versatile Laboratory Applications

Specially engineered for laboratory usage, this floor-mounted rig is fundamental in helping students and researchers analyze various aspects of hydraulic machinery. It supports practical learning and hands-on experimentation, enriching the educational experience in institutes across India.

FAQs of Francis Turbine Test Rig:

Q: How does the automatic operation method benefit users of the Francis Turbine Test Rig?

A: The automatic operation of the Francis Turbine Test Rig simplifies testing procedures, reducing human error and ensuring consistent, reliable results. This ease of use is particularly advantageous in laboratory settings, enabling students and researchers to focus on data collection and analysis rather than manual adjustments.Q: What is the primary purpose of using the Francis Turbine Test Rig in laboratories?

A: The main purpose of this test rig is to facilitate the detailed study and performance testing of Francis turbines under controlled laboratory conditions. It allows for observation, measurement, and analysis of hydraulic and mechanical efficiencies, making it a valuable tool for both instruction and research.Q: When is the Francis Turbine Test Rig typically incorporated into laboratory courses or research projects?

A: This test rig is generally utilized during academic sessions focused on fluid machinery, hydraulics, and renewable energy systems. It is also employed in research projects that investigate turbine behavior, energy conversion, and performance optimization.Q: Where can the Francis Turbine Test Rig be sourced in India?

A: The test rig is available throughout India via a broad range of channels, including dealers, distributors, exporters, manufacturers, producers, retailers, suppliers, traders, and wholesalers. These entities ensure timely supply, installation, and after-sales support to educational and research institutions.Q: What is the process of mounting the Francis Turbine Test Rig in a laboratory?

A: The rig is designed for floor mounting, which involves securely fixing it to a stable, level surface. Installation is usually performed by experienced technicians provided by the supplier, ensuring proper alignment and safe operation as per laboratory requirements.Q: How is the Francis Turbine Test Rig powered and why is this advantageous?

A: Powered by electricity, the rig offers reliable and consistent energy for experiments. Electric operation eliminates the need for manual power input, streamlining experimental procedures and supporting uninterrupted research activities.Q: What benefits does using a mild steel construction provide for the Francis Turbine Test Rig?

A: Mild steel offers exceptional strength and resistance to mechanical stress, ensuring the rig endures frequent use in dynamic laboratory environments. Its durability, combined with a corrosion-resistant finish, results in minimal maintenance and a prolonged operational lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulics and Fluid Mechanics Lab Equipment Category

Pitot Tube Apparatus

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Electric

Usage : Laboratory

Color : Blue

Operate Method : Automatic

Notch Apparatus

Price 5000 INR

Minimum Order Quantity : 1 Piece

Power Supply : Electric

Usage : Laboratory

Color : Blue

Operate Method : Automatic

Metacentric Height Apparatus

Price 6000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Manual

Usage : Laboratory

Color : Brown

Bernoulis Theorem

Price 6000 INR

Minimum Order Quantity : 1 Piece

Power Supply : Electric

Usage : Laboratory

Color : Blue

Operate Method : Automatic

GST : 33AVTPM1866A3ZI

|

|

SUBI TEK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry